I'm trying out brazing steel with the Bernzomatic Oxygen Torch for the first time. Check out how to build these these cool hand-tool bookends!

Read MoreReview: DeWalt Battery Adapter for 18 Volt tools to 20V MAX Batteries

Regular readers of this blog know that I've been personally wielding DeWalt 18 volt cordless tools on my projects for years. I love 'em; absolutely no complaints.

When DeWalt gave me an early-bird chance to try out their new battery adapter and bring modern battery technology to my older tools, I couldn't wait to put it in action. I've run it through its paces for a month on a variety of my tools.

I believe DeWalt's 18 volt line of cordless tools has been in the market for about 20 years. It's been one of the most popular lines of professional-quality cordless tools, for a very long time. They're certainly the most common brand on the construction sites I've visited.

I've had my own set for about 8 years, and all the tools are still going strong. They've outlasted and out performed any other brand of cordless tools I've owned by several years, leaving me a bit of a fan-boy.

This battery adapter is a huge deal. Years ago, I worked a second job, at a department store selling their popular exclusive brand of tools. It was common that I'd bear the brunt of a shopper's frustration when they learned that each year's version of the store-brand tools had an battery configuration incompatible with the prior model. It was odd, even though each generation was a same voltage, NiCd battery, there would be a slight change to a a bump or ridge on its case, preventing interchange between versions. People would end up purchasing new tools, rather than ordering older batteries from the factory. Was it an "engineered obsolescence" sales scheme? Although many people bought new cordless tool sets, lots left to shop elsewhere, swearing off the brand as they went out the door.

DeWalt on the other hand, has supported tools that last for a seriously long time. You can go to hardware store, home center, or Amazon.com today and get an 18 volt NiCd battery, or even a brand-new 18 volt tool. That's simply incredible, considering the modern system of 20V MAX tools has been out for 4-5 years. The introduction of this battery adapter is awesome; now we can start transitioning towards newer technology, bit by bit, piece by piece.

I own three 18 volt XRP batteries. I've worked them hard over the years. One recently decided it was time to retire and refused to take another charge. The other two are showing signs of age with their full-charge run time declining slightly. I'm still running them hard.

The grizzled veterans

These 18v batteries are beasts. They pack a lot of punch and run for a long time, even at their advanced age. I've never have trouble working two to three tools on a project, cycling between my three batteries. Now with one retired, I don't want to spend the dollars on replacements, when the modern stuff is so much better. The new Lithium Ion batteries pack much stronger punch with a better power to weight ratio, almost no self-discharge, and a cool led "fuel gauge".

Check out the size difference between the 2 amp hour Lithium Ion 20V MAX battery pack that came with my DeWalt Cordless Oscillating Multi Tool and one of my my beefy 18v XRP nickle-cadmium packs. There's a significant weight difference too.

NiCad vs, Lithium Ion

Obviously, there's more than a little physical difference between the old plunge-in style NiCd and the slide-on Lithium Ion. That difference is what the Dewalt Battery Adapter overcomes. It also holds the pack at a slight angle, presumably to mimic the tool balance we are accustom to with the old packs.

I slipped the adapter into my 18 volt Reciprocating Saw, just as I would the standard battery pack. It felt like it was of the same beefy plastic the tools are constructed from. There was a slight color variance, but I'm fairly sure that's due to 8 years of Arizona sun beating down on my tools as I work. Of course, I'm not going to complain about color variation, these are workin' tools after all.

The base of the adapter has the same electrical connections as the modern DeWalt MAX tools. The battery pack slides on from the front and locks onto the adapter.

Since February in Arizona isn't about shoveling snow, I let the DeWalt 18v Cordless Reciprocating Saw chew on some yard work for a bit. I cut palm tree fronds, trimmed the mesquite, and chopped up a dead cactus. I wasn't sad to see that stinker go either. It was the son-of-a-gun that seemed to shoot spines at me whenever I was in its vicinity. It still managed to get one last parting shot when I accidentally flipped a chunk up into the front of my shirt, leaving some painful little holes in my chest.

The saw ripped along, fast and powerful. It balanced good in the hand with the new batter set-up. I finished with plenty of juice in the battery.

Another adventure where I brought the battery adapter into play was the repair of our rooftop heat pump (Post: Cold at Night! A DIY Heating Repair Adventure ). I removed and replaced a bazillion screws with my DeWalt 18v 1/4" Impact Driver fueled by the 20V MAX Lithium Ion battery through the adapter. I ran the impact driver until the sun went down,...literally.

The battery adapter with the 20V MAX battery pack with worked just fine in my circular saw as well. Power and speed, making sawdust in the garage.

I understand the adapter works with most, but not all of the legacy DeWalt 18 volt tools loose in the wild, but it worked with my whole arsenal. I tested the rest of my collection with success. The adapter worked well with my cordless cut-off tool , my XRP Hammerdrill / drill / driver , and my flexible floodlight. The only complaint I have is that it takes a bit of extra muscle to remove the adapter; it seems to latch in tighter than the 18v battery packs themselves. Not a problem if you are just changing the batteries, but if you want to slip the whole deal on another tool, it takes just a little extra grunt.

I'm really happy with this cool widget. Frankly, I'm surprised DeWalt even produced it. Who could complain if they slowly phased out the 18 Volt line after such a long operational lifespan? Not only do they continue to support the older line, they chose to offer this adapter as a bridge to their current line. That's loyalty to your customers my friends.

I used a single 2 amp hour 20V MAX battery on my tools. I believe it outperformed the 18v XRP packs on their best day. DeWalt also makes larger-capacity 20V MAX packs, ranging up to a 5 amp hour beast.

The DeWalt Battery Adapter for 18V Tools is available now, in two configurations:

DCA1820 - DeWalt Battery Adapter for 18V Tools (inc. adapter)

DCA2203C - DeWalt Battery Adapter Kit for 18V Tools (inc. adapter, (2) 2 amp hour 20V MAX batteries, and a charger)

Keep an eye out, I'm going to be running this little champ on some upcoming projects.

This is not a sponsored post, but my friends at DeWalt did send me

a demo unit to try. All opinions and experiences are 100% my own.

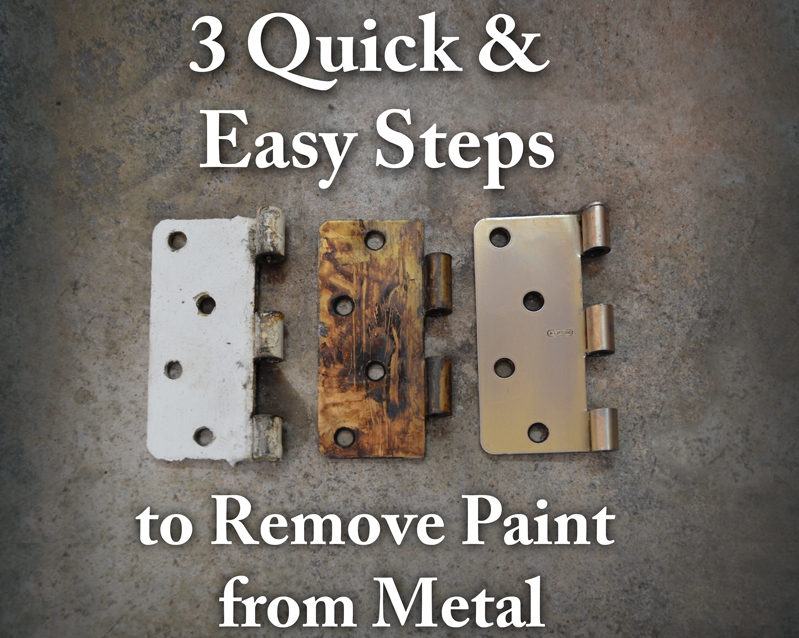

Remove Paint from Metal Hardware - 3 Quick and Easy Steps

Here's how I stripped the paint off these hideous, painted-over hinges with some Bernzomatic firepower.

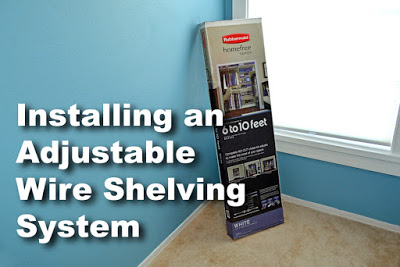

Read MoreInstalling a Closet Organizer - Easy DIY Project

I recently wrapped up the remodel of our daughter's closet, with the finishing touch of an adjustable organizing system. Because sometimes I'm a bit of a pea-wit, I posted the final reveal without showing the install of his final, key component. We'd picked out a wire rack style system for speed, affordability, and the ability to adjust it our kid's needs as she grows from her elementary school years.

I bought a starter kit boxed system, the Rubbermaid HomeFree 6 to 10 foot No Cut Closet Kit

from Lowes. There was a display at the store along with a good stock of add-on options. I'd be able to customize the system to fit our needs.

I started the install with a blank wall, freshly painted and ready to go. Of course, if you are not a regular reader, I actually started with a single shelf, cave of doom, closet of horror, many months ago. There was sooo much work in getting the wall to its current blank condition.

The cave of Doom

The install process started with locating the studs behind the drywall. Most of the weight needed to be held from solid framing, not the painted, paper-backed plaster of drywall.

It was a good thing too, I desperately needed an excuse to pick up a new toy, since my old stud sensor was toast. This cool little Zircon Studsensor e50 Electronic Stud Finder

did the trick nicely. It found both edges and projected an arrow for me to mark the target.

stay on target...

Since the far left edge didn't have a stud, I used one of the included plastic anchors. It had wings that folded inward to slip into a freshly drilled hole.

It got a quick tap tap from Sweetness to set it flush with the wall.

Sweetness!

Finally, there's a included little set-tool widget that comes with the kit. You push it into the drywall anchor, forcing the wings to splay out behind the drywall.

With the top rail screwed into that end anchor, I could pivot it until it was perfectly level. I pre-drilled through the drywall, into the studs and drove heavy screws with an impact driver.

.

This particular kit is expandable from 6 feet to 10 feet. The adjustability is accomplished by overlapping the top rail pieces, and telescoping outward until the space is filled. I drove the heavy screws into each stud, including the overlapped area.

There's a snap-on cover that helps space the verticals. I added a small one to space the first hanger a couple inches away from the wall.

The verticals simply hang on the horizontal bar.

A full-size spacer snaps into place, marking the location for the next vertical.

Each of the verticals got anchored to the wall with those same plastic anchors, just to hold them steady. The load bearing would be done from the horizontal rail, mounted securely to the wall studs.

The kit included extensions that hung from the verticals using a metal clip. They too got anchored in place.

The shelf hangers snapped securely in.

The wire shelves popped onto the hangers. At the rear of each hanger, was a sliding clip lever that locked it into place. Like the back rail, the shelves overlap and telescope to whatever custom length is required.

The shelf hangers do double duty by supporting clothes rod hangers as well.

I played around with several configurations, until I found one that I liked. I went with vertically stacked, double hangers, for the hanging clothes and a variety of shelves to hold her stuff.

I figure I at least quadrupled the horizontal storage on that wall by tearing out the single shelf and replacing it with this multi-level system.

A top shelf, high overhead would keep seldom used items for long term storage (or stuff that I want to get rid of, but our pint-sized pack-rat wants to hang onto forever).

No more wasted space, the entire wall is put to good use. I'm really happy with this Rubbermaid system. Although I was a first time user, I installed the whole thing in about an hour. It was incredibly easy to and looks pretty good for a kid's closet. The only negative I see is that we have to store her books horizontally or they will slip through the shelves. No biggie, I could lay a thin sheet of hardboard across those sections, if necessary.

There is even a shoe slipper (?) rack. Apparently it's so cool that our little lady actually puts her shoes away on her own, without being asked. Magic!

It holds Rudolph, rainbow star-spangled, AND panda slippers!

I had enough pieces and parts left over to customize a little section above the closet entry door, for more of that seldom used stuff. I had to take a hacksaw to the vertical pieces to fit, but it still worked out great.

I hope she doesn't spot that pain in-the-butt EasyBake Oven soon

Overall, it was a fun way to finish up the closet remodel. It was the step that made the little room functional, once again.

I may install the same system in our teenage son's closet too. It's a standard, front-facing closet layout, but it still uses that same single shelf with hanger setup that this walk-in originally featured.

The Rubbermaid system we picked up had plenty of expansion options on display, like drawers, baskets, and extra, original kit parts. I was able to build the configuration I wanted with the basic kit, right out of the box. I even have a few parts left over. I grabbed this particular kit for $178.00.

What do you think of wire shelving? I probably wouldn't use it in a master bedroom closet, but for kids, a pantry or a laundry room, I think it's perfect.

Non-Sponsored post.

Cold at night! A DIY Heating Repair Aventure

Ahhh, wintertime in Phoenix. Although it's considered a paradise this time of year, the nights do get a bit chilly in the desert.

At some point during the winter, we finally give up and turn on the heat. When it dips down in the 30's at night for a few hours, our tender carcasses simply can't handle the frigid, Arctic rush of cold. Live here and you basically become a cold-blooded reptile. My 28 years of Michigan-tempered, icy-veined fortitude are long gone. Nowadays, we're bone-chilled cold at temperatures where mid-westerners would be happy swimming in a lake.

During these recent chilly nights, it started getting getting colder and colder, inside the house. Coincidentally, throughout the week, we noticed the sound coming through the vents from the attic was getting steadily louder. Louder airflow-ish sounds, nothing alarming, yet.

During an extra cold night, the noise got downright ridiculous when the heat kicked on, like the sound of a box of silverware tumbling in a clothes dryer full of rusty nails.

That sound was alarming. Nothing could be done at 2:00 am on a work night, so I turned off the heat, pulled up the blankets, and dozed back off to sleep.

HVAC = Heating, Ventilation, and Air Conditioning

Our heat comes from a heat pump rather than a classic gas or electric furnace. As I understand it, in simple terms, it's our air conditioner running in reverse. Heat and cold come from the same unit, up on the roof of the house. I guess it's more efficient in our weather environment. (Here's the scientific mumbo-jumbo , if you care.)

Give me the choice between attic work and working on the roof and I'll choose fresh air and open spaces, free of crawling in the dust and scratchy insulation, every time. I'd be checking this problem out, up top.

You too, eh?

In an incredible coincidence of crazy timing, I had just read a blog post by Sarah at The Ugly Duckling House where she had successfully fought back a furnace failure with the help and advice of an HVAC knowledgeable friend. I won't spoil her story, but she got through the ordeal relatively unscathed. Go ahead and pop over there to read her post . I'll wait.

Back already? She got lucky, right? I was hoping that I was facing some sort of pulley, wheel, or bearing that needed some quick lubrication, 'cause I really don't have an HVAC friend.

A quick fix (?)

When I got home from work the next day, I turned on the heat, grabbed some penetrating oil and a can of WD-40, and tugged a ladder to the front of the house.

I scuttled up on the roof and opened up the side of the big metal box the noise was coming from, our AC unit. Inside was a blowing unit that looked a lot like the squirrel-cage floor fans that had filled our house after a big water leak a few years ago. I didn't need any expertise to tell that my pitiful, little can of WD-40 was not going to be the rescue hero I'd hoped it would be. The fan wasn't moving at all, but its central mounting hub(?) was completely detached and howling in fury. It was hard-core, metal-on-metal action, the hub was cutting into the inner edges of the fan vanes like a circular saw. Crap.

I pulled the fuse block, killing the power, removed the screws holding the fan unit to the duct-work, and pulled it back for examination. The fan was clearly destroyed, no fixing it. Some of the vanes were completely ripped off, others were bent, and then there was that whole thing about the central mounting hub being detached.

I buttoned the unit back up, climbed down, and started online research. Some sources recommended the complete replacement of the entire blower unit, motor and all. Best guess prices ranged from $400 - $1,000 to have a contractor do the work. Nope. Surely I could do it, right? Maybe I could even find the squirrel cage fan locally and perform the surgery myself.

Your Money is No Good Here

The next day, I spent my lunch hour driving around Phoenix to HVAC supply stores. What a freaking racket. While initially helpful, it was made clear that I couldn't get what I wanted because the supply stores wouldn't sell to the public. Apparently, I had to be a licensed HVAC contractor to buy parts; my money wouldn't be good in their fine establishments. One of my inquires was overheard by a grizzled HVAC tech slumped on a stool at the parts counter. This delightful gentleman treated me to a loud diatribe about how selling direct to "goddamn homeowners" took money out of his pocket!

I guess HVAC parts are distributed through a cartel or secret society that us bumpkin homeowners dare not be allowed to access.

Why is it you can buy electrical or plumbing parts at hardware stores, home-centers, and even grocery super-stores, but trying to buy parts for an HVAC system that you own, is somehow robbery? Heck, you can even buy automotive parts direct. I don't have a license to prepare and sell food, but I can sure go to any grocery and buy it to prepare in my own house. Old school, good old boy, supply-chain horse-crap, outdated in today's world, in my opinion.

Sorry dude. My house. My risk. My money.

If I hire you to do something and you bring your expertise, sweat, and disdain for handy homeowners, you can buy the parts. Otherwise let me fix my stuff. PS - I'm not calling your company anyway, Prince Charming.

Finally, I found a place that would sell me the fan. They still gave me a little trouble about the direct sale, but I talked them into it. It was just a fan, for God's sake, a few pieces of stamped metal. Forty bucks and I was out the door, in proud possession of my brand-new "blower wheel." If I could pull this repair off successfully, I'd save a bundle, as well as the time off work, waiting to meet a contractor.

Racing the Sunset

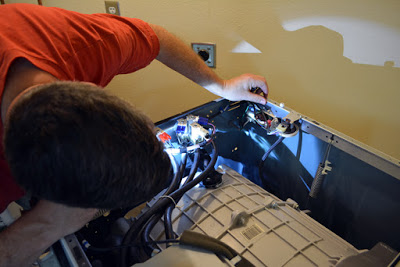

After work, I ascended the ladder again. This time I was loaded with the new fan, as many tools as I thought I might need, and a sack of the finest rooftop dining cuisine I could purchase through the closest drive through window. The sun was going down; I didn't have time to waste.

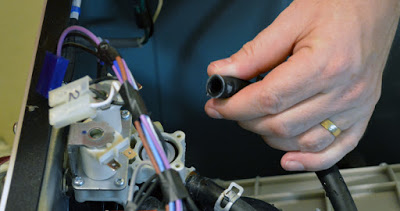

Rather than climbing up and down to flip breakers to disconnect power, I pulled the fuse block, right next to me.

AZ DIY Guy Scary Electrical Warning time

I buzzed the screws out of the side panel with the quick rat-tat-tat of my impact driver for the second night in a row. This time, however, there were cheap cheeseburgers and a big iced tea... so it was better.

McLovin' it

The mountains to the west, were looking hungrily at the sun, already starting to swallow it. Time was not on my side.

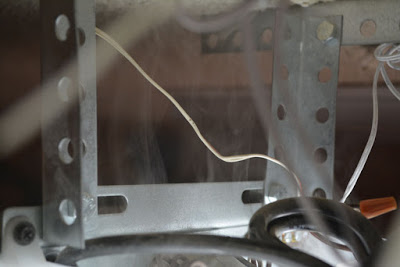

With the bent-up fan flopping around inside the housing, I had trouble getting the hub off the motor shaft. I put some muscle into my heavy linesman pliers and cut through the edges of the fan and pulled the beat-up thing out of my way.

Pro Tip:

The precise condition of our original fan is what a true professional may refer to as "toast."

"This damn thing is toast!"

- AZ DIY Guy

I still had a heck of a time getting that hub off the motor shaft, even with the set screw completely removed. Somehow, inexplicably, beating on it with the linesman pliers didn't do the trick. I finally doused the shaft with the magical elixir, and member of the holy trinity of DIY , WD-40. After a brief hit with 220 grit, fine sandpaper I slid the thing off the shaft.

Beating, pulling, prying, bending,...

At this point, I'll take a moment and share a couple of AZ DIY Guy's fans, young and old:

OK, technically, it's a couple "blower wheels", not fans.

I had to completely remove the motor from the housing to install the new fan. It's incredible that I can hold a motor in one hand that's powerful enough to blast air throughout the entire house.

With the new fan slipped on the motor shaft, the motor got reattached. The fan hub's set screw tightened to a flat edge on the motor shaft. I snugged it up tight.

There were sheet metal baffles and brackets to reattach before I screwed the unit back on the duct work. This was one of those tasks where an impact driver simply shines. The time saved by using one with a magnetic driver tip, versus a screwdriver is incalculable. It gets the job done quick, nice and tight, without stripping any screw heads.

Wait, what the heck is that?

I'm not going to insult my eagle-eyed readers and assume my fellow tool-drooling, DIY lovers didn't notice the odd, bulbous protuberance on the hilt of my beloved impact driver. My nine-year-old, Dewalt Impact Driver has run on beefy, 18 volt, NiCad batteries since the day I took it out of the box. Now, DeWalt sent me a 20V MAX* Battery Adapter to try out. It allows me to run the compact, powerful Lithium Ion 20V MAX batteries that powers DeWalt's current line of high-end tools. I'll have a review up soon, but so far, it's awesome. The adapter should be available through retail very soon.

UPDATE: You can buy the 20V MAX* Battery Adapter now, an Amazon best seller. Here's my review!

I was still worried. Was the shaft bent, the motor damaged, unbalanced, whatever? Luckily, after a quick hand spin, the fan spun smoothly. I could feel a good push of air. So far, so good.

I pushed the fuse block back into the disconnect and fired the unit up. It worked. Smooth as silk. Air blasted.

By that point, my reality, not illuminated by camera flash , was pretty dark. I fumbled the screws I could find into place with the LED on the impact driver for a while.

Finally, I couldn't see enough to finish. Stupid in the dark. I gave up and climbed down to fetch a flashlight. Illuminated, I buttoned up the side panels, gathered my tools, parts, and fast food debris, and made several trips across the roof to the top of the ladder.

As the last, feeble glow of the setting sun slipped softly behind the mountains, I managed to avoid falling off the edge in the dark to spend the night in a broken heap in the flowerbed. I didn't trip over any vent stacks or fall through the skylight as I cleaned up. Nighttime on rooftops should be reserved for Peter Pan and fairy-dusted children, not middle-aged DIY guys.

By the time I was done, the air was already chilly; I was more than ready to enter the freshly warming house.

The silly thing is, I had rushed to complete the repair after work, risking rooftop darkness, to avoid any more cold nights for the family. It turned out to be the last cold night anyway. As of this posting, we've had record breaking, warm temperatures for mid February. Today should hit 87 degrees with night in the mid 50's. Paradise. I could have waited for the weekend.

How about it? Would you tackle something like this, or fork over possibly hundreds of dollars?

Steampunk Table Lamp

I love the techno-industrial, sci-fi look of Steampunk design. Check out this DIY construction I created with copper tubing and a Bernzomatic TS-4000 trigger start torch.

Read MoreRemodeling a Kid's Closet - Final Reveal

Our daughter's closet remodel is finally, finally done. It took way longer than it should have, but eh,..life, right? Plus, this wasn't just a dab-of-paint type project; I ripped into and through walls. Sawdust flew, drywall crumbled, and the light of day burst into this little room.

Before - Wasted Space

The closet was a huge mess. Although, it was a walk-in, it was small, and simply didn't offer a good use of of space. The doorway is offset, preventing storage on both walls.

There was just one shelf on the left, with a clothes-hanger lip, essentially a six-foot closet rod with heaps of kid junk piled on top. A battered play kitchen sat against the back wall, too heaped with books and toys to offer a play space, much less decent storage of any kind.

To cap off the challenge, her room was technically not a legal bedroom. Our DIY Predecessors had put an addition on the house, essentially burying the bedroom in the interior of the house, without an egress window, or second means of escape, in the event of a fire.

The Battle Plan

I boiled the project down into a three point scope:

- Add a window to the exterior wall, for natural light and an emergency exit

- Trim the window, remove the shelf, repair and repaint the walls

- Create and expand storage to make it usable beyond the elementary school years

Following is a quick chronological tour of the action as it went down. I'll share links to the original posts, in all their detailed glory, at the end of this post.

Please forgive the odd-angled photography; it's damn near impossible to frame good shots inside a 4x6 closet.

Demolition Party

We emptied the closet of Legos, army men, fast food happy meal toys, books, stuffed animals, loose change, and even a secret stash of fruit roll ups. There were some happy discoveries along the way, long lost toys and treasures.

I ordered the minimum size window to meet the egress requirements and laid out a rough opening with painter's tape. It was going to be a real trick to install shelving and a closet rod with the window effectively taking up the entire back wall. Eh,.. I'd figure that out later.

Gracie decorated what would be the opening with sharpies and more tape.

She was going to be a part of this project as much as possible. She was on hand to build a temporary clothing rack and load all her clothes so they could hang out in the dining room for a couple weeks several months.

We tore the self / hanger combo out together. The wall was pretty torn up, with nearly 40 years of paint and caulk build up and damage from who knows how many families moving in and out.

Luckily, for this project, we have a wood sided home. I hope to stucco it at some point, but for now, it just took a bit of saw-work to slice the exterior siding open. I later took a whole sheet off, in order to get at the framing from the outside.

Studs had to be cut out and reinforcing framing had to be put into place to form the rough opening. Man, I just

love using a framing nailer. There was even a little plumbing that had to be redone for the exterior spigot and the swimming pool's auto-fill device.

The wall cavity got fresh insulation before being sealed up again behind a new sheet of siding.

I punched through the drywall, trimming it flush with the new, rough opening.

I waterproofed the opening and slipped the brand new window into place. Exterior trim would come later.

Interior Trim and Walls

Back indoors, I wrapped the interior of the window opening with select pine, to hide the framing, insulating foam, and waterproofing membrane.

I trimmed the window with various sizes of select pine, creating an easy, nice-looking Craftsman style look. There were no miter cuts, just 90 degree butt joints. It's an experiment to see if we like it, before we replicate it elsewhere in the house.

My helper returned to repair the walls. She absolutely loved it; she absolutely made a mess. It was great.

I deployed my high tech, dust-extraction system in an attempt to keep drywall dust from getting everywhere in the house during sanding.

(Note: High-tech, dust-extraction = blowing a cheap fan out an open window)

Since this was a small wall area, I didn't deploy the big texture blaster I'd used on the family room remodel . I just used the canned stuff and sprayed the wall.

As sort of a project within a project, I decided to slice into the large, blank wall and create a recessed shelving unit. Why cover the wall with posters when some extra storage space could be stolen from the inner recesses of an interior partition wall?

I peeled a large section of drywall off, revealing the sweet, secret space hidden within.

It was not load bearing, but it was a big cavity. After I removed a couple studs, the opening got re-framed with 2x4's to keep the wall nice and stable.

Gracie and I built the shelf carcass in the garage with 1x4's pocket holes and bead board.

I pocket screwed a couple horizontal shelves in place and attached a face frame to give the piece a built-in look and give it just a little more depth.

This was a fun, little bonus addition to the closet that will grow over time, starting with Minecraft, Pokemon, and Shopkins toys. In the future, she will likely end up filling it with nail polish, perfume, or whatever our future teenage Gracie wants to load them up them with.

The finishing touches

Gracie chose blue walls. Don't even try to tell her blue is not a girl color. She'll probably bounce you off the sidewalk and tell you that, "YOU are a girl's color." Blue it would be then, with crisp, white trim.

Years ago, we had to have someone come to the house to measure and custom order cellular window shades. Now, thanks to the miracles of modern science and engineering, an average Joe can simply walk in from the street and snag them off the shelf at their local home center. No more Winnie the Pooh bed sheet for a window shade.

With the new window, slightly in the way, I couldn't use any form of end-to-end shelving. I went with a clean, white, wire shelving / organizing system, suspended from a horizontal support, screwed into the wall framing.

The system is adjustable, able to resize and adapt, with Gracie's growing need. We loaded it with plenty of shelves to hold her stuff. Some are far above her reach, for seldom used items.

Clothing hanger rods, were also included, with clips to hold them beneath a shelf.

The Final Reveal

The finished closet is chock-full of grade-school age, mighty, girl-of-action stuff. It's got natural light, with an egress window for safety, and a bit of fun style.

It's gone from from a boring, faded cave, heaped with debris dating back to toddlerhood to a colorful space with contrasting trim and shelving. The room looks and acts completely different.

Books don't do well vertically on wire shelving.

It's got plenty of storage and organization room now. We've pulled items into the closet, like the dirty clothes hamper, freeing up even more play space in her room.

Is it still technically a "shoe rack" with 75% slippers?

I even had enough leftover shelving pieces to build this little rack over the doorway, for stuff we rarely use.

Honestly, I hope she forgets about that God-awful "Easy bake" oven.

With free space opened up in her bedroom, naturally we find Gracie spending more time playing and reading in her closet.

The curator in her element.

A glutton for punishment?

If you want to read the how I did it detail, step-by-step, as well as some of the decision making points in this project, check out the sub posts that tell the entire tale. Pour yourself a beverage, sit back with some munchies, and treat yourself to the whole story:

- Closet Remodel and Emergency Escape

- Adding a Window: Framing Fun and Foolishness

- Adding a Window: Sliding on Some Siding

- Adding a Window: The Install

- Super Easy DIY Craftsman Style Window Trim

- DIY Built-in-the-Wall Shelving - Reclaim hidden storage space in your home

- Installing a Closet Organizer - Easy DIY Project

I'd love to hear what you think of this one in the comments below. Thanks for reading!

Review: DeWalt 20V XR Lithium-Ion Oscillating Multi-Tool

I picked up a DeWalt 20V XR Lithium-Ion Oscillating Multi-Tool recently and ran it through its paces on a recent, closet remodel project. Spoiler: I'm really pleased with it.

An oscillating multi-tool is a handy class of tool that features an interchangeable blade or attachment that rapidly rotates back and forth, on the horizontal axis. The blade travel is slight, nothing like the inch or so of travel of a big, bad reciprocating saw. These tools can make fine cuts in difficult to reach areas, even straight, plunging cuts. Many brands of Oscillating Multi Tools have appeared over the last several years, along with accessories beyond cutting blades.

My first OMT experience

I became more familiar with the somewhat new class of Oscillating Multi-Tools, having started with a cheapo import model that sold me on the concept. I bought the thing on a whim, on a weekend coupon sale. I found loved the things a multi-tool could do. I've used it to slice door molding, cut drywall and siding, trim bamboo flooring, and even hack shingles.

It was a perfect type of tool to have in the cabinet, and got more use than I thought it would. I loved the concept, but I did have issues with the tool itself. I tore up the cheap wood cutting blades like crazy. Blade changes were a pain and I had to periodically re-tighten them the with an allen wrench. The tool was loud and sent a lot of vibration up my arm. I decided to replace it because it got really hot under extended use, feel the heat through work gloves hot. Still, I got a decent life span from the tool, considering the price.

The Upgraded Experience

I wanted to a cordless model, so I decided to buy the DeWalt, the #1 Best Seller seller on Amazon.com, with a 90% five-star rating. The version I bought is the DEWALT DCS355D1 20V XR Lithium-Ion Oscillating Multi-Tool Kit which came with a bag and a bunch of accessories. This kit costs a little under $200, less for the bare, cordless tool less if you already have enough 20V MAX batteries and prefer to buy the attachments a la carte. A similarly outfitted kit can be picked up for about $50 less for the corded model. I've also seen it included with some of the larger, cordless combo kits, if you are financially blessed enough to bag a sweet pile of new lithium-ion power tools in one swoop, and make me horribly jealous.

blade mounted 90 degrees to the tool

I figured these things were suited for nail encrusted wood, so they'd be good for cutting bare framing nails. I think there was too much wobble in the way I was holding the tool. I managed to dull the blade up more than I'd hoped, but it worked.

Using Off Brand Blades

The next task I tried was to cut a large drywall opening for my in wall closet shelving project. For this cut, I used a blade I already had in inventory. It was a Harbor Freight, 4" crescent shaped, steel blade. with the wide, curved tooth edge, I could cut a long line, changing the angle of the tool, so my grip and arm position could be adjusted for comfort. DeWalt makes higher-quality, similarly-shaped blade, but I wanted to test the included universal accessory adapter included with the kit I'd purchased.

This piece utilizes a the bolt and washer type connection similar to my old tool, but it snugged up much tighter. It allowed me to use the off-brand blade without any issue.

An off brand blade mounted via the Universal Accessory Adapter

Oscillating Tool Guide System

Cutting those long, straight lines freehand was a concern before I started, but it was a piece of cake. First of all, this tool is smoooooth.

I don't know if it's better build quality, or the brushless motor, but the DeWalt didn't vibrate and rattle as much as my old tool. It positively purred in my grip. Fitted with the removable DeWalt Oscillating Tool Guide System

(included in the kit), I was able to roll along, pressing the guide against the wall as I went, for added stability.

Oscillating Tool Guide System

It's stable enough to comfortably cut one handed, almost like a pair of scissors.

One-handed, overhead cutting, using the Oscillating Tool Guide System

Accessory Changes

The DeWalt uses a tool-free, accessory clamp system, with a big spring-loaded lever and those gripping teeth I mentioned earlier. The tapered teeth slip into holes in the blade and grip tight. This is one of those features I didn't know I missed when using my original tool. I had simply dealt with hunting around for the special Allen wrench to make changes and periodic re-tightening.

Quick, tool-free blade change

Battery life

I challenged the multi-tool during my project, by performing plunge cuts inside the wall cavity through 2x4's. I completely cut through the boards in four places; two locations were actually doubled 2x4's. I sliced a couple nails in the process too. All of this, including the drywall cutting, was done on a single battery charge, with juice to spare. DeWalt claims a 57% increased run-time due to the brush-less motor. I was really pleased, because I only have the one 20 V MAX battery on hand. My aging fleet of cordless tools are running on last generation, monstrous Ni-Cad batteries that I couldn't swap into the tool.

The tool was powerful, yet lightweight and easy to handle. I could fit the thing inside the wall cavity, with enough room for my fingers to grip it. Of course, my entire hand wouldn't fit in there to pull the trigger comfortably, but there is a trigger lock feature to keep it running, something else my original tool didn't enjoy.

Tight Spaces

It plowed through the cuts fairly quickly. Of course, it was slower than a reciprocating saw would have done, chewing full-speed. I probably wouldn't reach for this tool in an open stud-wall situation with both tools on hand, but that's not what it's made for. This little soldier is a commando, trained for precision strikes, in difficult-to-reach territory and, with a variety of accessories, it's prepared to take whatever weapon it needs to complete that mission.

Plunge cutting a 2x4

Light it up

Seriously? A headlight? It's another feature I would not have actively added to my shopping list, thinking it a silly inclusion, like dealer added pin-striping and mud-flaps on a car. However, at the end of the day, I absolutely loved it; I was lining up my cuts on pencil lines, hiding in the shadowy recesses of a wall cavity. It was awesome.

In fact, at one point, because I can be an idiot, I dropped my remote camera trigger down inside the wall and simply shined the tool's LED headlight down the wall to locate it.

(Note: The Oscillating tool does not include any feature whatsoever to reach three feet down inside a tight wall cavity and fish a feeble-fingered Blogger's critical, photography item out. Disappointing, you'd think they'd have thought of that and added some kind of Bat-Grapple thing. I gotta deduct points for this omission.)

Bright idea

I found the tool versatile and enough to use throughout the entire project, I even used it like a pair of power shears to cut the beadboard backer. I rough cut it to size, then trimmed it flush, once it was tacked in place.

Detail Sanding

I popped on the sander accessory and gave my project a good once over. The kit I purchased includes this fitting, plus a decent supply of sandpaper, in three grits.

How do you like my dust extraction system in the background? Wintertime in Phoenix baby!

Detail Sanding attachment with 120 grit

No complaints on the sanding, I slipped a piece of 120 grit on the hook-and-loop pa and went to town. I rounded the edges slightly, cleaned up my puttied nail holes, and gave the whole piece a once over, including the inner corners. The tool was easy to handle. I loved not having to fiddle around with a clumsy power cord while I sanded the piece.

Bottom line, I really like this tool. I'm sold on the concept of a multi-tool in general, but this DeWalt came through with everything I wanted, and more. It's well balanced, powerful, and gets great battery life. You will not be disappointed if you add this gem to your DIY tool arsenal.

This is a non-sponsored post, but I have included Amazon.com affiliate links for your convenience. If you make a purchase through one of my links, I'll earn a modest commission to help run the site, at no additional cost to you. Thank you for all your support.

DIY Water Heater Maintenance and Custom Drain Upgrade

It's been a year and a half since we replaced our aging water heater. The old one had become filled with sediment, rusted, and its elements burned up, destroying the unit. A water heater is an expensive appliance to replace. I don't want to do it again anytime soon, so I decided I'd do annual maintenance on it.

I also wanted to upgrade the cheap, plastic drain valve from the factory. With all the experience with soldering I've gotten this year as a Bernzomatic Torchbearer, I figured I'd craft a custom valve assembly that would allow me to direct a drain hose in a gentle sweep towards the out-of-doors. More on that in a minute.

The project is easy in concept, disconnect the unit (power and water), drain it, check the sacrificial anode rod, and replace the valve. Piece of cake , in concept. Disconnecting electricity was the easiest. I'd installed a simple shut off switch a couple years ago. It was an easy project that keeps me from running outside to shut off the power at the circuit breaker. Flip the switch and the unit is dead.

The water was also easy to disengage. When I'd installed this unit, I'd added valves on both the hot and cold water lines. (Of course, I'd reversed the red and blue colors for some pea-witted reason). I also turned on the hot water to the laundry tub, to empty the line a little.

Moving merrily on to the next step to drain the water out, I attached a garden hose and opened the valve with a screwdriver to let the water flow freely.

Yep -"flow freely". Dang it. It was completely jammed up with sediment. I couldn't get a drop through the hose. Even with the valve removed, only a dribble of water seeped out. This would not be the easy, piece-of-cake I'd imagined.

I started poking a piece of electrical cable in through the drain hole and twisting it around. I got a little water and oatmeal-looking sediment to come out.

After a healthy bit of poking, I got water and crud flowing a little faster. There wasn't enough pressure to push all the way through the hose, so I used a handy drill-powered pump to suck the water out of the broiler pan I was using to catch the gunk (shhhh...don't tell my wife). I started making a pretty nice mess, too.

Uuuughhhh...

When I figured I had enough water out of the tank, I opened the pressure release valve to reduce the vacuum in the tank. It helped speed up the flow.

After a while, I was able to hook the hose up with a 6" threaded nipple and empty the tank. I turned the cold water back on and off a few times to flush the rest of the sediment out of the tank.

Temporary loose valve.

Finally, I got to start building my new drain valve assembly. I wanted a threaded 90-degree bend that was close enough to the tank to prevent tripping over. It also needed to be removable, in case I had another sediment clog.

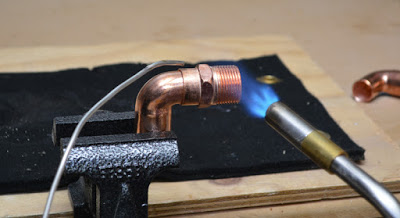

I clamped and cleaned a piece of 3/4" copper pipe and a threaded fitting, preparing them for soldering.

A little flux on both sides of the joint and the first piece was ready for the heat.

I laid down the heat on the fitting side of the union causing the flux to sizzle and bubble. The TS8000 High Intensity Torch is the sweetest, smoothest torch in the Bernzomatic line. I love its one-handed operation and the ability to upgrade from propane to hotter MAP-Pro gas.

The Bernzomatic TS8000 High Intensity Torch

This particular torch is good for larger pipe. On this 3/4" stuff, it was an absolute breeze. With the flux quickly bubbling under the ultra swirl, high intensity flame , I clicked the torch off and touched the seam with the solder which melted and was sucked into the gap.

A quick quench from damp rag and the piece could be safely handled.

Since this is going to be an exposed piece, I touched it up with a quick dash of sandpaper. Beautiful.

I've really come to enjoy the satisfaction of making a nicely soldered piece. It's actually fun, when you get the hang of it.

I'm really sold on the MAP-Pro with the TS-8000. It gets the piece hotter faster, really speeding up how quickly the solder will liquify. I think I'm sticking with MAP-Pro for my future soldering projects.

I repeated the same steps as I pieced together the new drain assembly.

Clean and Flux

Heat the fitting side until the flux bubbles and sizzles

Melt that solder!

The custom drain elbow was competed with a cleanup and a few wraps of teflon tape to the threaded fittings. This custom piece is quite a bit longer on one end due to the extra thick insulation of our water heater.

Back at my now soaked and spattered worksite, I threaded the new piece carefully into the drain hole of the heater. When I measured for the elbow, I'd marked the pieces to ensure that it would be parallel to floor when the piece was full threaded in place.

I'd chosen to install a threaded faucet rather than a soldered-on model so that I could remove it and spin the whole assembly off later. If I'd permanently attached it, the assembly would be too large to spin off in the event of another clog.

Done deal! The faucet I installed had a removable handle, so I could avoid having little hands messing around and spewing scalding hot water on themselves, flooding the garage. I hid the handle on top of the unit.

The last maintenance step was to check the anode rod. These are sacrificial shafts that stick into the tank from above and corrode over time. It's made from a material that is more susceptable to corrosion due to electrolytic action, so it gets eaten up before the lining of the tank. It greatly extends the life of the unit.

I'd picked up a rod when I was at the home center, so I was going to replace it regardless. It was a matter of popping a cap off the top of the unit, scratching some insulation out of the way and unscrewing it with a big 1 1/16 " socket, on a 1/2" drive ratchet.

It was a little chewed up, but would probably last another year or so. Still, I wanted to replace it anyway while I had the tank empty and the water off. Water heaters are expensive.

It was tough to get out because there was a low ceiling in that area due to a heating and air conditioning duct. I had to bend it.

The replacement anode rod was actually jointed, allowing it to flex in order to drop it into the tank. Handy, eh? Just a little teflon tape on the threads and screw it into place.

Note that this unit is an electrical model. I shut it down with the flick of a switch. If you have a gas model, you're going to want to turn off the heat before draining it. Check the manufacturer's instructions for a safe shutdown. Make extra sure there's no gas escaping while you work, especially if you are doing some flaming torch work in the area.

I filled the tank back up, fired up the power, and cleaned up the tools. Maintenance done. Next time it will be easier if I don't wait for the thing to fill up with gross sediment. Plus, I have a nice metal valve to speed the process. I think I'll adjust up to a 6 month draining schedule, just to keep it ship shape. I'd

autopsied our old one after I tore it out. I never want to see that absolute horror again.

Maintain your heater and save serious money down the road.

This is a sponsored post. I am a proud to be a Bernzomatic Torch Bearer, though all opinions expressed are 100% my own. I won't recommend products I don't believe in.

The Torch Bearers are a group of tradespeople, DIYers, culinarians, adventurers and artists brought together to create projects using Bernzomatic torches and share their knowledge and ideas with you. Check them out here and get inspired to create with fire.

Visit the other awesome Torchbearers and see what they are up to on the Bernzomatic Torch Bearer Site.

Favorite Stuff DIY 2015

2015 Favorite DIY Stuff: DeWalt Lithium Ion Cordless Oscillating Multi Tool, Bernzomatic TS8000 Trigger Start High Intensity Torch, Keen Utility Braddock Work Boot, Uvex Safety Glasses, Bessey BV-CO30 Clamp Base Vise

Read MoreDIY Built-in-the-Wall Shelving - Reclaim hidden storage space in your home

How to add a beautiful, built-in shelving unit into a wall.

Read MoreCutting with Fire: DIY Metal-Cutting with an Oxygen Torch

This year, I've been trying out all kinds of handheld torches, using several types of fuel. The tool geek in me really wanted to challenge myself and move up to something even more serious. Luckily, I got my hands on a

Cutting, Welding, and Brazing Torch Kit , the big, hot Mamma of the Bernzomatic line.

I've done recent torch projects with butane (up to 3,150° F), projects with propane (up to 3,600° F), and projects with hotter burning MAP-Pro (up to 3,730°).

The Bernzomatic OX2550KC, is the next step up. It uses a dual-gas fuel setup; burning both MAP-Pro and pure Oxygen. This compact, fire-breathing beast can produce a flame up to an incredible 5,300° F! It's not even a commercial tool; it's something you can pick up for yourself at a hardware store or home center.

I wanted to try cutting metal with fire. I'd never done anything like it. I think this torch in cutting mode is probably best suited for metal stock, perhaps around 1/8" thick or so. So, naturally, I decided to push well past that on my very first task. I'd been wanting to remove an old, bent fence hinge from our block wall. It was there when we bought our home and has always been an eyesore. The trick would be to cut it off behind the face of the block, so I could patch over it. A reciprocating saw would be difficult to use in that spot. I'd bend the heck out of some blades, chip the wall up, and rattle the heck out of my arms.

It's time to go, Mr. Bent Hinge Pin

This torch doesn't work like a standard handheld torch, it takes a bit of fiddling to get the hang of it, but it's incredible when you do. After a little practice, I was able to perform the fine dance of easing more and more gas into the flame, making it hotter and hotter, a blue/white blade of flame.

The Bernzomatic OX2550KC Cutting, Welding, and Brazing Torch Kit This is a hose style tool, with fuel cylinders placed remotely, away from the torch head. Starting the torch requires opening the MAP-Pro valve, ever so slightly and using a handheld sparker to ignite it.

“Come on Baby, Light my fire.”

It takes a different approach, too much gas flow and the flame will go out with a quick blast and a "pop!"

Since I'm used to using a standard, handheld torch which can be instantly lit with a hearty blast of flame, it took me a several tries to figure out that I needed to use a very light touch. The MAP-Pro fueled flame needed to be quiet and soft, waving gently like a stick pulled from a camp fire. I learned to ease the MAP-Pro flow down even more, until the base of the flame barely touched the torch nozzle.

Isn't it soft and cuddly?

Next came the oxygen. Its valve appears to be finely threaded, because you can turn it quite a bit before the oxygen gets flowing. It's great for controlling the release of a very small amount of gas and easing it up slowly. Too much oxygen, too quick, and "pop" out goes the light. In that case, everything has to be shut off to safely start again.

Speaking of safety, you'll note I stepped up my gear a couple notches for this project. First,since there would potentially be sparks and molten metal, I wore long pants and shirt sleeves (in Arizona even!). Beefy, long-wristed welding gloves would protect my hands if anything spattered. I capped my natty ensemble off with some Mad Max eye-protection, exchanging my normal safety glasses for a shaded, welding mono-goggle. I wouldn't take any chances with my already crappy eyes and a blinding, white-hot flame.

Fire, when you can't see the whites of my eyes.

As I slowly eased more oxygen into the flame, it snapped from the slowly waving, orange flame, to a crisp jet of blue-white fury. To cut with this rascal, I had to get it as hot as possible. It took a few tries, but I got the hang of dancing my hand between the MAP-Pro and Oxygen valves, until I got a real tight blast going.

The perfect flame of awesomeness

With my finely-tuned fire-knife ready, I eased the absolute hottest point up to the metal hinge. The tip of the innermost cone of blue flame was the sweet spot. It was a 1/4" of legendary dragon-fire.

I slowly eased the cutting tip of flame back and forth, ever so slightly, watching the metal turn red-hot. Soon, the surface was liquified and starting to flow. I could move a gelatinous blob of molten metal around with the tip of the flame.

I was really getting going when the flame died out. Getting the initial feel for working the tool sucked down quite a bit of oxygen. I'd run out, just when I was having fun. I ran out to the hardware store and grabbed another, which was perfect, because they had just finished making the first batch of popcorn for the day.

The second time, with the learning curve behind me. I got my flame ripping in no time. I was once again in the molten metal business.

"Hot"

As I cut, it seemed like the liquid metal helped accelerate the process, it kept the hinge piece stay glowing hot.

The camera, just doesn't do it justice. Even through the shaded goggles, it looked incredible, like a movie scene from a steel mill. It was too fun to be work.

Hotter

I tapped on the piece few times with a pair of pliers and could easily bend it. A couple flaming minutes later, I grabbed ahold and snapped it off without effort.

Hottest

Although the red glow faded very quickly, the piece was still dangerously hot. I could feel the heat radiating from it on my weekend-stubble chin. Even after cooling on the ground for several minutes, it still scorched the board I set it on like a wood burning iron.

It was a shame I was done. It was just too much fun.

Naturally, the kid in me decided I really needed to push the remaining bit of metal back, just a little deeper into the block face, because,... molten metal!

I sparked up some fire again. I really had the hang of lighting the torch by this point, quickly getting the flame into good cutting shape. With the flame concentrated in a recessed hole in the block, it created an oven of incredible heat, liquefying the metal in seconds.

The Bernzomatic Cutting, Welding, and Brazing Torch Kit really is a cool tool. I pushed it hard on my first foray, not only cutting, but cutting a really thick piece of metal. I think I may do a more crafty-dude project with thinner metal at some point. I'm also looking forward to using it to try brazing, basically a big-kid version of soldering, to weld metal together.

What do you think? Ready to try this powerhouse of flame?

This is a sponsored post. I am a proud to be a Bernzomatic Torch Bearer, though all opinions expressed are 100% my own. I won't recommend products I don't believe in.

The Torch Bearers are a group of tradespeople, DIYers, culinarians, adventurers and artists brought together to create projects using Bernzomatic torches and share their knowledge and ideas with you. Check them out here and get inspired to create with fire.

Visit the other awesome Torchbearers and see what they are up to on the Bernzomatic Torch Bearer Site.

10 DIY Tips for Troubleshooting and Repairing Appliances

One of the best things about being a rabid (crazy) Do-it-Yourselfer is the confidence slowly gained to tear things apart and repair them (or attempt to). Home appliances are no exception. They can be expensive to replace or have repaired. Why not save some money and DIY it if you can?

I just worked through a repair and have some general tips that can help with whatever busted appliance you may need to tackle.

For the second time, our washing machine needed the fix-it treatment. Of course, a problem appeared right in the middle of the closet renovation project, so it was another weekend lost to on that project.

The first time I'd cracked open this washing machine, the inner drum had leapt off its hanger springs and smashed two of the three stabilizing pistons. It wasn't a physically easy repair due to the massive, heavy drum, but it wasn't all that complex to figure out either. It's been two and a half years and that fix is still holding.

This time, it was a leak, indicated by a peculiar, growing stain on the concrete. By the time we realized it was an honest to goodness leak and not a spill, it had destroyed a framed painting stored beside the stackable units.

Water Damage

I'm not the Maytag Repairman, or anything of the sort, but I do have at least four, serious household appliance repairs under my belt over the years. I've saved thousands of dollars in the process. As a result, I'm not afraid to take a crack at a repair, even if I don't know 100% what I'm doing.

Risk vs. Reward

When considering if I'm going to DIY a repair, I look at risk versus reward. In the case of the washing machine, I figured that a new, front-loading washing machine costs somewhere between $650 to $1,200. Home Advisor states that professional repair costs normally range from $120 to $500. My thought is that, as long as I don't damage or destroy anything worse than it is, I can still fall back and call a real repair service,.. and make an appointment,... and hope they show up,... and don't try to scam us. Of course, I could also just run out and pick up a new machine. After all, that is why we have credit cards, a right?

My usual approach is that I am at least going to try to DIY it first. I'm going to share a few of my tips that have led to several, money-saving success stories.

Tip#1: Clear the area.

Seriously, open up the area where you are going to work and give yourself some elbow room. Don't waste any mental energy worrying about bumping into or climbing over stuff. A cluttered work area wastes time, too. It's so easy to lose parts and tools as you mindlessly set them down on or around piles of stuff that are simply in the way.

Tip #2: Centralize your Tools

It's bad enough that I cannot do any home improvement project without misplacing at least two tape measures per hour. I think half my time is spent looking for where I set them. It's the same for these repair projects, I set tools down everywhere, even leaving them in the kitchen when I go in to grab a snack.

I've started keeping an empty tool tote under my workbench. When I'm off to another location around the house, I'll load it with what I think I may need and take it all with me in one trip. It saves a ton of back and forth wasted time. Also, I try to get myself in the habit of dropping tools back into the box every single time I set them down, instead of scattering them around me on every horizontal surface I can reach.

Tip #3: Turn off / Disconnect

Unless you are specifically testing a particular system (electricity / water / gas), turn it off and / or disconnect it. None of this stuff is good to mess with in an unknown troubleshooting situation.

Electricity: It's important to unplug an appliance before working on it. Electrical terminations inside are not always shielded from contact. It's usually a big, electrically-conductive metal box you're working on. Trust me, electrical shock isn't cool.

With your hands inside a machine, it's best that the chance the machine turning on be prevented. Surprise moving parts could cause injury.

Water: At the very least, turn off the valve feeding the machine. There's no reason to be faced with a geyser of scalding, hot water. I disconnected the feeds too. I'd have to hook them back up later to ensure I found the leak, but initially, I wanted the area clear without stuff to tangle me up.

Gas: I don't have any gas appliances, but it stands to reason that it's a good idea to turn off the gas to an appliance before you start monkeying around inside. I can imagine a host of disasters that can be caused with live, flammable gas.

Tip #4: Nothing but the 'Net

Nowadays, it's just the dimwit, living in a van down by the river, that doesn't do a little online research first. In my search, I found common sources of leaks for our exact brand of LG washer. The most likely culprit was a bellows looking piece of plastic in the drain area. There were even step by step videos and part numbers.

According to the videos, that repair could be done through the rear access panel, which meant I wouldn't have to disconnect and remove the heavy dryer, stacked above. That was one pain-in-the-ass maneuver I really hoped to avoid.

The access hatch to the detention level

Unfortunately, when I started poking around inside, I realized the water was not coming from that commonly failing drain piece in the lower front, but dripping down from above. It was coming from the vicinity of the water connections, but I couldn't see where.

The effects of gravity on water.

That was an awesome discovery. Just awesome, because,.. this...

Do it yourself back-pain.

Searching the web, I found the exact way to easily open the exterior case without breaking anything. Most appliances have a specific order of things that have to be done, like one of those wooden puzzle boxes. Trying to figure it out on your own is time consuming and can lead to busted plastic tabs, bent metal, a surprising amount of scraped knuckles, and the spewing of remarkably filthy language.

This particular front loading LG opens up by removing some screws from the back, sliding the top backwards a few inches, then swinging it up and off. With the right instructions, I didn't waste time taking too many screws off, just the couple I needed.

Tip #5 - Speaking of Screws... Don't lose them.

There is nothing worse than the losing small parts as you work.

Whenever I'm taking an appliance apart, I always use a magnetic metal bowl / dish thing.

to keep my small metal parts in. It's not a sexy power tool, but trust me it will save you more heartache than you can imagine by avoiding lost screws and metal parts. The one I use has a rubber padded magnet so it doesn't scratch a painted surface. I just slap it on the side of the appliance and toss the screws in it.

Tip #6: Sherlock Holmes time

Take your time and do a thorough inspection looking for clues to the problem. Take your time.

Think.

If there had been a mechanical problem, I'd be looking for rub marks, dents, or something bent or out of place. Remember when this very same washer tried to self destruct? That didn't take much sleuthing with the drum laying on the floor of the case.

Read about that fun repair from 2013 here:

An Emergency Washer Repair Challenge.

If it was a suspected electrical or electronic problem, I'd be looking for heat damage, burned wires, scorch marks, or damaged circuit boards. Years ago, I found what I think was a over-heated sensor, obviously burned-up in a dead dryer. I replaced it and the problem was solved.

This time it was a leak. I was looking for the highest point I could find any evidence of water, because water is always going to flow down right? It could of course be a red herring, if I found moisture too high in the case. It was possible that there was enough pressure from a leak to spray upwards.

A flashlight and and inspection mirror are handy in this step. Even sticking a cell phone camera into out-of-sight areas is a good trick. Snap photos and zoom in on them to see hidden problems.

Elementary, my dear Watson.

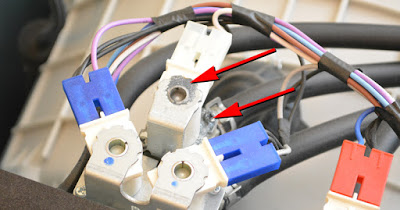

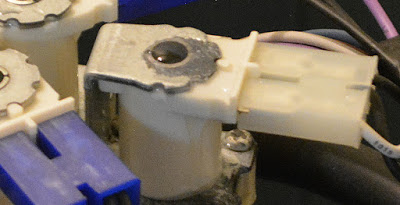

In this case, right up at the top, I noticed some discoloration in the metal on one of the parts. It really didn't look right, compared to the other pieces in the area,

That had to be it. I re-attached the water lines and turned the water on, thinking I'd run a test wash cycle.

As soon as the water was on, the leak appeared. This thing leaked under standard household water pressure,

constantly. I hadn't even plugged the machine in yet and rivulets of water were already streaming down the side of the plastic cylinder.

Tip #7: Decision Making Time - To DIY or Not to DIY?

Up until this point, I'd just opened up the outer shell and poked around. No real parts had been monkeyed with yet.

This is the time for a gut check and decide if it's time to call in the professional. It's a decision you have to make for yourself, based on your level of confidence, tolerance for risk, and understanding of what you've found. If you decide to call in a professional, no shame in that.

At least (in this case) I'd located the problem. I could snap a photo and show it to a repair technician, lessening the time they'd be troubleshooting. Heck, I could even email photos to repair companies and ask for a quotation.

Of course, my loyal readers know my tolerance for this stuff. Be it confidence or stupidity, I reach for the tools and start pulling stuff apart. In this case, it was a couple screws that held the part in place.

With the part in hand, I had the advantage of my brief career as an electrician to recognize it as a "solenoid."

A solenoid is a simple concept, it's simply an electromagnetic plunger. Basically, some control function sends a flow of electricity to a coil of wire inside the part which magnetically drives a piston in one direction or another. Usually there's a spring holding it down in an unpowered situation. This particular manifold of solenoids had control wiring to each one and a rubber water line leading away. All three were grouped against the cold water source. So this little bugger was supposed to be pushing down on a small water valve keeping water from flowing through until it was needed for whatever part of the wash cycle that needed it.

With water leaking out of it constantly, the part was in a condition known amongst the well informed as "broken" or "messed-up." I'd have to replace it. I popped the simple little wiring harness off and headed back inside to find the part online.

It didn't take too long to learn that I could not buy a replacement solenoid after all. I'd have to buy the whole cold water inlet valve assembly. I found them all over the place with various prices and shipping options.

This time I made a couple calls and lucked out and supported my local economy. I guess it doesn't help to give Art's Parts a shout out, since they are closing the location. They were great though, staying open a few minutes late, on a Sunday! with the part waiting for me when I got there.

Tip #8: Label, Label, Label!!!

When you are taking stuff apart that can go back together in different locations, it's a good idea to label it so it doesn't get crossed later. I like to number them from left to right.

I took a sharpie to the wiring harness clips.

I did the same with the water hoses as I removed them. I could read the black marker on the black tubes,...

while it was fresh. In hindsight I wish I'd wrapped them in masking tape to write numbers on.

Tip #9: Plan for the mess

Water spills, greasy hands, steaming capacitor juice , or just trash, it's good to think ahead for the mess. I try to have a trash bucket nearby, some rags, and, as in this case, a catch cup for removing water lines.

With the wiring and hoses disconnected, the act of removal was a piece of cake that took about one minute. I just had to take out a couple screws holding the assembly in place.

Tip #10: Double check new parts

If you didn't take the old parts with you to the store, or you ordered your parts online, it's always good to make an eyeball comparison of old and new before opening the package. If you open the packaging, you may not be able to return an incorrect part.

Even out of the packaging, I make a good comparison. There's no sense in installing an incorrect part that might cause problems.

Refresher: Remember that Label, Label, Label thing?

The black marker on black hoses disappeared of course. Even though I could see it when I wrote it, it was gone by the time I got to putting everything back together. I really had to make a guess, fitting them back on by length and the existing curves in their shapes. I got lucky.

Tip #11 Test and Check BEFORE Closing Up

I was fairly confident I'd put everything back together the way I'd found it, but there was a possibility that the new part was faulty, that I'd damaged a water line, or screwed something up. I hooked the water lines up and turned the valve.

With full, city water pressure pushing against the repair, I spent a few minutes closely watching and feeling around for leaks. Now would be the time to find a problem, not after screwing everything back together. In this particular configuration, I certainly didn't want to go through the hernia inducing, back-breaking act of stacking the dryer back on top if I wasn't sure the fix was a good one.

Luckily, it was a good one. Thank goodness, no more leaks. Before I sealed up the case and restacked the two units, I left it overnight with a big floor fan blasting downwards. Both the concrete floor and the washer guts needed a good drying out. This repair was a success.

Tip #12 Know When to Throw in the Towel

Despite my successes, I've had failures too. I've also decided to purchase new, rather than attempting a repair.

I've irreversibly destroyed an expensive Keurig coffeemaker by poking around inside trying to find a blockage. Now, we've switched over to exclusively using distilled water in the replacement Keurig, it simply does not get clogged up.

I've torn into an old refrigerator too, without ever being able to find anything obviously wrong. I don't know anything about refrigeration and I certainly don't have the specialized tools. The unit was old enough to be worth replacing anyway. I posted it on Craigslist for free and got rid of it.

I've cracked open an old water heater to find the damage too extensive and beyond my skills. Even a professional would recommend replacement. After I replaced it, I performed an autopsy and confirmed I'd made the right choice. The thing was toast.

That's it, tips for my approach to repairing appliances. Again, I'm not an expert and I'll certainly call in the pro's when I'm uncomfortable.

In my home-owning life, I've saved thousands of dollars by tackling these repairs myself. I've fixed more than big appliances with this approach. I've repaired garage door openers, video game controllers, a vacuum cleaner. a treadmill, a vehicle audio jack, and other stuff. I have a friend that even repaired a flat screen TV, just by figuring out which circuit board had a burned spot on it and replacing it.

Let me know if you have any luck, next time an appliance threatens an early demise.

Tips for Using a Handheld Torch Safely

I've been doing a bunch of posts about projects using handheld torches this year and I have a lot more to share in the coming months. Torches are sweet, fire-spitting tools that really aren't scary to work with. Like any tool, they just have to be treated with respect and they are perfectly safe. I've going to share some safety tips and one ferociously close call that could have burned our house down.

My first rule for using a torch, is to stay mindful of my surroundings. Combustible materials inadvertently set ablaze could lead to disaster. I avoid or protect flammable stuff. I always do this. In fact, in the past, you've seen me use window cleaner to wet a wooden area, then add a flame proof mat, like when I plumbed to replace a hose bib on the back of our wooden-sided, very - flammable house.

Flame-proof mat in action.

Pictured Torch: TS4000-Trigger-Start Torch Head (with propane)

Like I said, I always do this. Unless, of course, I'm being a moron...

Recently, you may recall me weeding the yard with a Bernzomatic Lawn and Garden torch. Trust me, it's pure joy to incinerate and kill weeds this way, plus there's no nasty chemicals to deal with. In order to share this pure joy with you on this blog, I puttered merrily about the yard, flaming weeds. I moved my camera tripod around with me to capture the hard-core, flame-throwing action.

Good bye.

All was going well with this marvelous, photo-journalistic endeavour. I walked from the front yard to the side, sending weeds to their smoking doom and snapping pictures. I set the camera down over a particularly leafy little weed to get a close-up, before-and-after shot (all for you, dear reader), I leaned over to squint through the viewfinder and set the focal point, which of course was...

Mistake #1.

A particularly leafy weed.

With my face pressed against the camera, I heard a single, sharp cracking sound that made me think perhaps someone coming up behind me stepped on a dry stick. When I turned around, the sound instantly transformed into a fast, frying-bacon crackle and a sickening "whoosh!" I took a leisurely full second to stand, slack-jawed, with a burning torch in my hand, wondering how in the world I had managed to set a huge pile of dried palm fronds on fire. Flames exploded upwards, rapidly climbing the pile. The heap was stacked and waiting politely for bulk trash pickup a couple weeks later. Now it was rapidly and rudely turning into a flaming hell, just a few feet away from the house.

I clearly remember saying, "Uughhhtt!!!"

Sometimes in life, situations occur where curse words just don't do it. In the moment, I couldn't recall any actual words, curse or otherwise.

I shut off the torch, set it down, and ran at the pile. I knocked the biggest of the burning pieces off the stack with the sort of Kung-fu, whiptail kick maneuver that comes naturally to a person in fight-or-flight situations like this. Trust me, you would do it too, instant Kung-fu master style. I began to stomp my work boots on those flames, crushing them into submission.

Thank the heavens I hadn't been a complete idiot wearing sandals; boots were perfect. Oh, how I wished the camera had been facing the pile to see that bad-ass, action hero kick and stomp action. I even had the remote trigger in my hand the whole time, but the camera was pointed at that dang, particularly leafy weed. I was sure my Kung-fu firefighting moves looked cool.

No, they weren't cool at all, nor were they effective. The action hero bit evaporated away instantly. I had scattered glowing embers in my initial kicking and stomping assault that each latched hungrily onto fresh, bone-dry fronds. I continued to kick and stomp as fires continued to flare.

It was a loooong time that I leapt around in an insane hybrid dance. I was getting exhausted. The initial shock had worn off. I realized I wasn't losing the battle, but I clearly wasn't winning either. I was going to burn out before the fire would. I didn't think it would get to the house about 6 feet away, but I couldn't be sure. Even if it didn't, I really didn't want to have a neighbor call the fire department when they noticed the smoke. They'd probably present me with a nice, big fine.

As I furiously danced and singed my leg hair off, my first thought was the garden hose. Could I unwind it from its hook in the front yard, turn it on, and run it all the way back around before the entire pile was engulfed? As I got ready to run for it, I noticed the pool remodeling contractor had left it in a tangle, about 5 feet away from the place I was furiously doing the crazy stomp dance. There was absolutely no way I'd get that mess working in time.

Nope. Nope. Nope.

How about the fire extinguisher?!!! Of course goofball! I had brought it out of the garage when I started torching.

Unfortunately, I had also left it in the furthest side of the front yard when I walked around the house, which of course was...

Mistake #2

I got a second burst adrenaline-fueled energy and ran faster than I had run 20 years, sliding in the gravel and spinning narrowly past the treacherous, spiked Saguaro cactus to grab that little red cylinder. I was back to the inferno in seconds, ripping the pull ring, and blasting the conflagration. The world disappeared in a massive cloud of yellow powder. Ever your devoted blogger, I spun the camera around for you to see the second, smaller blast.

Good times, eh? In the end, I know I was super lucky. What if I had rounded the corner and not heard that first crackle? The truth is, five solitary minutes of this pile blazing without any defensive fight could have cost us the house.

Scary, but easily avoidable. In this one, rare occasion, I didn't give my tool proper respect and it bit me. Moron.

Basic Torch Safety

Bernzomatic provides excellent documentation with their torches, plus they have some great resources on their general safety information page. Work safe. Don't be a moron

Here are their basics a nutshell:

- Read the safety warnings and instructions

- Use gloves and safety glasses

Blog Post:

Removing Rusted Bolts with a Torch - Fire it up!

- Check the seals. Don't use cylinders with damaged or missing seals. Get rid of cylinders with dirt or rust in the valve areas.

Blog Post:

Yard Cleanup - buckets, a pole saw, and a torch!

- Turn off a torch before attaching fuel. Hold the cylinder vertically when attaching it.

- Do not use tools to tighten, hand pressure only to avoid over-tightening.

- Check for leaks. Use soapy water on the connections and look for bubbles. Listen for hissing of gas. Feel for coldness. Smell for a rotten egg odor. Do not use if a leak is detected.

- Keep torches upright to prevent flare-ups or flashes. If it sputters or flares up, turn cylinder upright and turn it off. Vent unburned gas from the area.

Facebook Gallery:

Torch Lighting the Grill and Spiral Dogs!

- Allow torches to cool off. Remove fuel and replace caps.

Blog Post:

Re-Plumbing an Exterior Hose Bib - Fun with Fire!