This technological terror is a hand crafted ULTIMATE garage workshop power strip.

Read MoreLoose ends - The Art of Incomplete

|

| Yes. That's an old throwing star back there. I don't know why. |

|

| Proof that Frog Tape does have long term holding power. |

|

| I even crossed the wires so we have to turn on the exterior lights to make the office light come on. Not fixed. |

|

| Full disclosure, the power tool part is actually fun. |

|

| I wish I could start over on this one, but I've put too much cash into it. |

|

| Chunk Chuck-er |

There and Back Again

|

| Ok. Gracie did have a little wood work project to do. |

|

| Allow me to show you to your seat sir. |

|

| Pita chips anyone? |

|

| Take this back to Hobbiton please. |

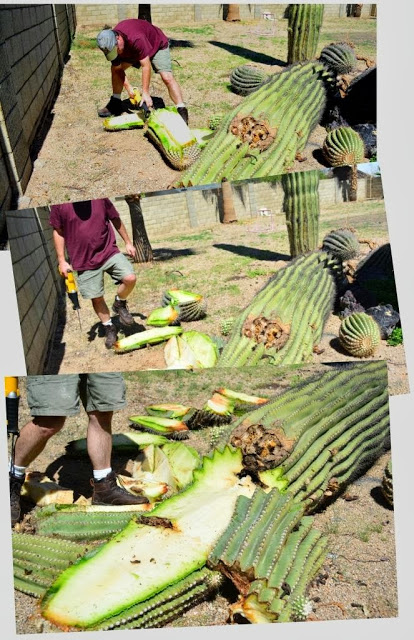

How to remove a fallen 16' cactus from your back yard

|

| The grand inspector, surveying the scene. |

|

| Slice 'n dice |

|

| Don't tread on me. |

|

Photo tip: It's considered much more manly to have a work truck parked in the

background, especially when it looks like you're raising the flag over Mt. Suribachi.

|

|

| That's the little bastard that got me. |

Re-securing the Border (Not that Border)

|

| "...earlier this summer" |

NOTICE: It has come to our attention that some of the stakes sold with our EcoBorder "L" product last year (estimated time frame between July and August 2012) have a raw material defect. In our ongoing efforts to use recycled materials in our products, we have learned that some of the recycled raw material plastics used in those stakes (we expect about 3% of product sold over that time) have this issue. Due to an adverse reaction from some impurities found in those materials, some stakes purchased in those months could turn white. With product quality and customer satisfaction as our top priorities we apologize greatly to any customers that have experienced this. In response, we vow to "make it right" with any customers that this may have affected.

If you were affected by this issue, please email us a photo (to: mail@ecoborder.com) of the stakes along with a count of how many replacement stakes are needed. In response, we will send out top quality replacement stakes at no cost to you. Once again, we apologize for this issue and will do whatever it takes to make sure that you our customers see our unending dedication to a quality product and customer service!

EcoBorder knows there was a very small lot of stakes that were discovered to have a defect in a UV protecting ingredient. They've adjusted suppliers and resolved the issue. It's been difficult for them to locate the affected batch, since it's scattered across the country, carried by the two big home center chains.

A supply of fresh replacement stakes was quickly shipped. I received an email with tracking information. They arrived a couple days later.

Oh, How the mighty has fallen!

You can only imagine how it felt to get home from work one afternoon and head out the back door, to check on the pool, only to find one of the most striking features of our back yard destroyed. It was a stop-cold-in-my-tracks moment...

|

| Aaaaaaghhhhh!!! |

|

| Pay not attention to the horrible porch; it's on the list. |

|

| The inspector. |

|

| This 60 lb. ball punched a 3 inch deep dent into the flower bed. |

|

| Graboid juice |

|

| This isn't your little window-sill garden cactus my friends. |

*As my Facebook followers know, I've referenced Tremors twice, recently. I don't know why. I guess it's time to bust out the DVDand visit Val and Earl. I do miss those idiots.

The Great Debate: Hiring a Pro vs DIY (Replacing Swimming Pool Equipment Edition)

- A new cartridge filter to replace the aging DE filter (the big R2-D2 looking thing) so back-washing and dealing with that messy white powder is a thing of the past. Old leaky here has been a maintenance nightmare. It would need hundreds of dollars in replacement parts if we wanted to save it. A cartridge filter will reduce my maintenance time greatly.

- Replace the pool pump. The existing motor is doing fine, since the it was replaced a year ago (home warranty!!!) but, we expect to save about $700 annually in power consumption by upgrading to a modern, variable speed pump. Plus, the unit is tired and has air and water leaks.

- Adding a salt water cell. This is actually exciting. We are going to nearly eliminate our chemical dependency (and cost!!!!) by converting salt water to chlorine. Everyone I talk to who's made this conversion has loved it.

|

| No swamp. |

|

| Swamp. |

Homework: There's a neat article Marcie Geffner wrote last year for Bankrate.com, titled Remodeling Yeilds Rewards, Vexations where she compares my successful family room remodel experience to cautionary advice from the authors of Home Improvement For Dummies. I do their cautionary, contrasting point of view vs. my gung-ho, I-can-do-anything approach. Doing research, I found their website diyornot.com, which provides lots of info on DIY vs. hire. It's a very good site. I just get a vibe that it's pushing the hire direction a bit hard, especially with an apparent choice of advertisers directed towards for hiring contractors. Maybe I'm a bit sensitive because I love the do it yourself approach. Heck, I have ads for tools and materials on my site. - John

A Relaxing Labor Day Project: Underground Electrical

Even though I'd proclaimed it a no-project weekend, I started excavating the slab the equipment is sitting on. I thought I'd be nice and hopefully avoid the cost creep of having a pool tech digging at $80 / hour before dropping down a new slab. I dug it out pretty quickly.

|

| One of the many leaks dribbling away. |

Of course, it wouldn't be a ripping good DIY Guy project experience if it ended as neatly as that, would it? Nope. Remember Murphy's Law, my friends. I noticed this little gem of awesomeness:

|

| "Don't you call me a mindless philosopher, you overweight glob of grease!" |

conduit, wrapped in corrosion preventing rubber tape. Awesome. Guess what else?!!! There's cement covering it too. Oh, joyous day!! But that's not all; there's a thunderstorm bearing down on me. Sweeeeeeeeeeeet, now this is a holiday, my friends!!! So much for BBQ, it's going to be a carryout pizza night.

|

| The conduit on the left and the gounding box on top are brass, and in perfect condition. |

|

| Can you tell the new from the old? |

|

| 100 degrees and humid after the storm. It's not quite as fun as it sounds. |

I put all the wiring back exactly the way it was before. I recommend you don't mess around with electrical near a pool if you're not really comfortable with it. Seriously, hire an electrician. There's a whole section of code devoted to it.

|

| Generally, you don't see pools this color outside St Patrick's Day |

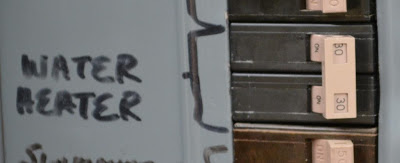

Installing a water heater shut-off switch

Last time, I mentioned I couldn't quite get to a water heater maintenance program without doing some repairs first. I figure step number one is to bring the electrical up to snuff. I decided to install a disconnect switch by the unit, so I don't have to trudge to the outdoor electrical panel every time I want to shut the unit off.

Before I could get going on this part, I had to replace the breaker. My predecessors had installed two, single pole breakers, rather than one double-pole 30 amp breaker. Not cool my friends.

AZ DIY Guy's Scary Warning - Electrical Edition: Don't mess with electrical, unless you know what you are doing. 120 volts of household current can kill you just as dead as much higher voltages, it just lets you suffer longer, and folks can still recognize you in your casket. Plus, electrical issues can do a heck of a job burning your house right to the ground. When in doubt, get a professional electrician. If you do the This project is a snap for someone who's trained; it shouldn't cost too much. Even if you know what you are doing, I recommend you work it like it's live, even if it's not. Research legal requirements in your area before making changes to your electrical system. Finally, don't take my word for this stuff, I might be some random idiot on the internet.

No. Not cool at all. Those are separate breakers. I picked up a breaker at Home Depot for about 13 bucks. It was an easy swap; just a matter of turning off the main breaker for a minute while I slipped the two originals, popped the new one in, and re landed the wires.

Of course it couldn't go perfectly. I noticed, for the first time that this particular circuit's wiring was aluminum. I hate that I have aluminum wiring. More on that later.

Cool. Very cool indeed.

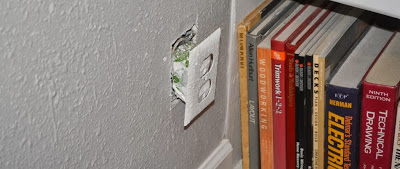

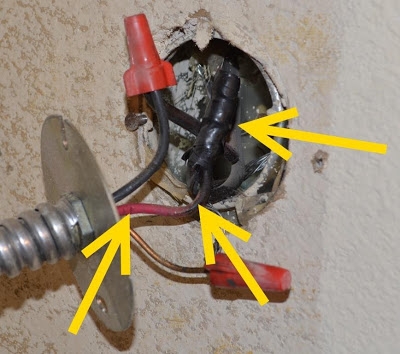

I turned off the new 2 pole circuit breaker and moved inside to open up the junction box to find,... a gob of black electrical tape, discolored wire, and nicked insulation (clockwise below). Not good signs.

Since I don't trust ANYTHING in this place, I like to do a quick check to see if the circuit is still live. Especially if there's some sketchy-looking wiring where I'm about to stick my fingers. Idiots could have easily landed one of the hot wires to the wrong breaker; it could light me up. No thanks. It's time to reach the Bat Belt for my trusty non-contact voltage tester.

.

.

Apparently, It's pretty serious.

Ahhhhh,... sweet silence. The circuit is dead.

This is scary. The wire nut inside the tape glob is completely destroyed. Worse yet, where is the rest of it? There were no fragments or pieces of more than half of it, not in the tape, not in the junction box. To me, this means some mental giant actually knew this was busted and wrapped it in electrical tape, rather than simply installing a new wire nut. This could burn a house down to save the effort of installing a cheap wire nut. Jackassery! I think it's especially unsafe in that it's aluminum to copper wire junction.

That's an identical, complete wire nut on the right.

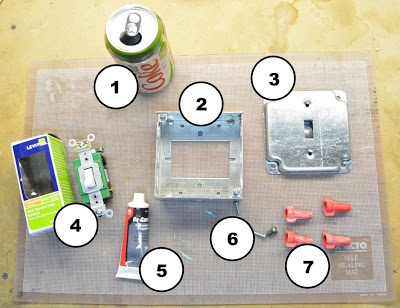

Back over to the workbench, I set up to prefabricate the switch assembly. Here's the stuff:

Diet Coke Lime The lime is important. I can't find the reference exactly, but it's in the National Electrical code somewhere,...promise.

Square Box Extension Ring. This will extend the in-wall box allowing for more room to fit the switch and wiring.

30 Amp, 2 pole switch I chose Leviton's extra heavy-duty spec-grade.

Anti-Oxidant CompoundThis gunk is required when you tie copper to aluminum wiring.

Screws: 8/32's to screw the window box, and one ground screw to ground it. (... to rule them all!)

Wire Nuts ..you know,...to nut wire.

I clipped the ears off the switch, so it would fit nicely behind the plate.

I pulled the existing 6/32 mounting screws out of the switch, since they're not needed here. Next, I stripped some new #10 copper wire and installed it behind all 4 termination screws, the line side (the "home run" to the breaker) on the black screws, load side (to the heater) on the brass.

No, the WD-40 and the big ol' bottle of blowin' bubbles are not necessary.

I like to put a wrap of electrical tape around the device, leaving a folded, courtesy tab for easy removal later.

Pop the cover on with the two short 6/32's (included with the cover) and we're ready to install.

The extension ring installs on the wall, screwed to the back box in the wall.

The stripped, bare copper and aluminum wires got a good bit of the anti-oxidization goop. Man! I wish we didn't have that aluminum wiring. At least it's only on a few circuits in the house.

All wired up and sealed in place. I slipped on a 90 degree flex connector, pulled fresh new wire to the heater, terminated it, and sealed everything up.

Flip the breaker and power it up. We should be in business, just in time for the next laundry cycle. Now I can shut the whole thing off whenever I'm finally able to drain it for maintenance.

Look good?

To check the voltage, I popped off the front cover, peeled out a piece of insulation, and exposed the internal wiring terminations for the the heating element. Careful, careful,.. 120 volts from both of the hot conductors to ground and 240 between them. Done!

240,...243.7, whatever it takes.

Next time kiddies, it's on to plumbing. I have to repair or replace that corroded, seized shut-off valve. I'll have to do some research on that one.

Before servicing the water heater...

I found that water heaters should be drained and flushed as much as twice a year?!!! and the sacrificial anode rod

What a great opportunity for a blog post on water heater servicing right? Drain it and check the rod, piece of cake. Let's do it this weekend kiddies!!!

Nope. Because of this stuff I need to deal with first.

A) within sight,... or

B) capable of being locked in the open position (power off) position.Our electrical panel is outside, as is common here in Arizona. Technically, we may be ok, since the breaker can be locked out (if I buy a lockout kit). It's fuzzy, the locking means is supposed to be there even if it's not locked. Either way, I don't like it. Electrical code is minimum. I want better in my own home, so I'm going to install a switch.

Just to spice things up a bit, I just found another little Inheritance from my DIY Predecessors. Instead of the 2 pole, 30 amp breaker, they installed two 1 pole 30 amp breakers. Not cool, IMHO. The two pair in the yellow circle should look like the three in the blue below. It's not safe to turn off or trip half a 240 volt circuit, both should turn off together.

|

| Alas, this fine, Shakespearean penmanship is not mine to claim. |

|

| Crust is good on apple pie, not on plumbing. - AZ DIY Guy |

I suppose I'll start with the electrical. Hopefully, I don't discover anything else shocking. Check in next time as I head towards eventually getting on a regular maintenance program.

PS - Do I at least get points for making it through the whole post without calling it a Hot water heater?

Moving through another door

This time it was Jack's bedroom that got completed. His door had sat, half-painted for four months or so, while I tackled other pressing projects (see the index, April through July). I do get off-track.

I pulled his (young) man-cave door, complete with HAZ-MAT warning and an electrician's lockout tag-out tag out off it's hinges.

I've also started monkeying with the new DSLR camera and tripod, so "action shots" of yours truly are possible. Although, seeing my mug isn't much of an improvement, I can finally show some better photos than the ol' camera phone, and share some updates to my methods.

|

| Cooooooooookies!!! |

|

| Yes,.... that's the mighty, still not finished, organizer project under there. I'm not proud. |

Step 1: Slop some glue on toothpicks. Make sure to open the box in such a way that you spill them all over the floor as I have, otherwise the technique won't work. If you're wearing nice clothes to work in (ahem, Jeff), a damp paper towel is nice to have on hand.

Step 2: Jam a three or so gluey 'picks in the hole and savagely snap them off. There's no need for ceremony here. We're cleaning up after barbarians. Note: The spattered glue on my hands is a controlled exercise, just an educational illustration of one possible outcome, if you get overzealous in the glue application. It would never happen to me in real life. I'm sacrificing for you, dear reader.

Step 3: Run the screws in. Pro tip: I like to turn my screws in clockwise, otherwise known in the scientific circles as "righty-tighty". Do it your own direction, I'm just sharing what works for me. Again, I used the insulated #2 Phillips tip screwdriverbecause, well.... I don't know.

Review: Ryobi Door Latch Installation Kit

Reviewing the Rayobi Door Latch Installation Kit in action.

Read MoreBefore and After: Family Room

|

| Late 2005: The prior owner's stuff, as they were departing. |

|

| Early 2006: the dusty television years. |

|

It's hard to believe this 6 year old, Alien Bounty Hunter is now a teenager.

|

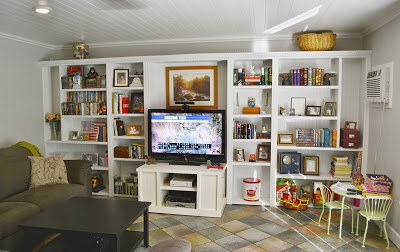

We spruced up the shelves in 2006 with molding, bead board panels, and crisp, white paint. I built a custom TV stand soon after. In about 2008, we installed french doors. There the room sat for years, with its horribly, stained, way too low (7' 5") drop ceiling and the ceiling fan finial that hung 3/8" below the peak of my melon-shaped head.

|

| It's a bit busy, but it's our main hangout. |

|

| The kid infestation is still in full bloom. |

|

| I used a lightweight foam crown molding to cap off the book cases. |

|

| The french doors got capped off with the same dentil molding. We used Jeld Wen doors with the built in shades from Home Depot. |

In case you mist it: Installing a cooling mist system

Luckily, our super-dry climate lends itself very nicely to evaporative cooling (and swimming pools!). Most restaurants with outdoor patios and amusement park lines employ a misting system to keep folks cool in the summer. Water flows through tubing and is forced through very small nozzles, vaporizing and cooling the area as much as 20 -35° F (11 - 20° C) in seconds.

|

| Sweetness |

|

| Yep, that's some nasty corrugated fiberglass stuff. |

|

| I've seen fire and I've seen rain... |

|

| They like their 'dogs blackened. Don't blame the grill master! |

For the sake of updating,... and stuff

|

| Time to make the donuts... |

I have fiddled around with the site a bit, adding some favorite story links in the right margin for new visitors.

I've also launched a new side project. I thought I'd chronicle my adventures in learning photography. After a long saving's program, I've finally pulled the trigger and ordered a fancy new DSLR camera. Check out my little side project, AZ DIY Guy's Photography Adventures.

|

| http://azdiyguyphoto.blogspot.com/ |

Well it's off to Jury duty, a 15th wedding anniversary with my beautiful bride, and two Meet the Teacher nights this week,... plus, maybe a last coat of paint on this door? Have a great week my friends!

Installing an Oscillating Ceiling Fan / Fishing Wires (It's hot up here)

Problem: the blades of his ceiling fan spun right through the sleeping area. I told him to scoot over against the wall and not roll around much, but Sweetie convinced me Child Protective Services would have an issue with my solution. So, I removed the fan and installed a simple light fixture. Unfortunately, during the hottest summer nights, it's been warm for him, up by the ceiling. A floor fan just doesn't cut it.

|

| The lens is missing as a result of an unfortunate incident with a N-Force Vendetta Sword |

|

| See the black AND blue wires? |

I say "prepared", because that's as far as I got. Why? because I was an over confident putz. In my steely-eyed, experienced-fan-installer confidence, I hadn't even glanced at the instructions. I hadn't paid any attention whatsoever to the fact that this fan had two wires, one to control the fan, the other to control the oscillating. The existing house wiring only had one wire. Moooooron.

|

| Attic work. I hate attic work. |

|

| W.W.M.G.D. = What would Mac Gyver do? |

|

| Here's my rig. |

|

| Hmmm... AZ DIY Guy, It doesn't look to miserable in the picture. |

|

| Crazy from the heat. |

Installing drip edge, or maybe not...

I'm really trying to wrap up the work on the front of the house. All that's left is replacing the drip edge that was removed when our predecessors built the dreaded tunnel of doom . I'd also torn off a good amount when I replaced the rotted facia boards.

Drip edge is a sheet metal flashing strip that slides under the roofing and over the top edge of the facia. It has a slight kick at the tip that kicks water off, away from the wood to keep water from ruining it. Here's a good look at the old stuff I'd removed a few weeks back when I tore out the facia.

You may have noticed, my normal practice is to attack a project in a frenzy like a shark on the scent of blood until about 90% complete. This is normally where my eye wanders and I leave the project, moving on to the next. I don't recommend this, and I don't have any good excuse; I'm just letting you know my style.

The problem is that this time it's obvious. not only is there a bright white metal strip missing on part of our roof line, but there's the issue of the remaining shingles not being fastened very well. I'd pulled nails and staples in my demolition. Our area suffered a pretty strong storm last week that uprooted trees and ripped up roofs, even clay tile shingles. We were mostly spared, but there was a little issue with loose edge shingles.

I got up early this morning, to beat the heat but couldn't really fire up the air compressor to nail it without waking the neighborhood.

At least I could get to the quiet work of measuring, cutting, and dry fitting the edge. This stuff is hazardous. Just touching it, you can feel it really wants you to slide your bare hand along the edge, just once, so it can rip your tender flesh open. It wants to taste blood. I denied myself a trip to urgent care for stitches and slipped on some gloves.

I took a quick tour around the rest of the house to see how the existing drip edge was installed around corners and peaks. It's pretty easy with a pair of tin snips. Here's an outside corner.

I slipped it into place, under the shingles, overlapping the next piece of edging. In some parts of the country, there's additional steps, such as getting it under the underlayment to prevent ice damming. Nothing we need to worry about here in Phoenix.

Heck, it almost never rains anyway.*

There were a few missing shingle parts from the storm. Luckily, I still have a scrap pile I can find some pieces to scavenge and cut here and there.

In one case, I happened to find the exact missing puzzle piece laying over by the neighbor's yard. I tucked him back in under his blanket, nice and cozy. I'll come back and fasten it later, when I nail in the edge.

I got the garage dry fitted and started wrapping around to the front, where the tunnel had been.

The trouble is, I had cut through two layers of shingles in the middle of the roof face to remove the section over the tunnel. The old roof buried below was sticking out too far. I'd have to trim it back, flush with the facia somehow. I tried a razor knife, but that was ridiculously difficult. I ended up using my oscillating multi tool, even though I only had a wood / plastic blade on hand. It did really good when cutting from below,...

for a while.

Yep. I destroyed the blade in a few short minutes.

I guess it's a trip to the hardware sto...."Boom!,... BOOOM!,... BOOOOOM! ....BOOOOOOOOOM...."

Someone to the south of us was evidently doing a reenactment of the cannonade, preceding the last charge in the battle of Gettysburg, early Sunday morning, no less.

Ahhhhhh,... crud.

Normally, I'm accustomed to seeing a bright blue beautiful sky over there. A couple more flashes and deep rolling booms re-awakened my long dormant Michigan weather sense.

"Fuuuuuuuuudgggggggge....." - Ralphie Parker

Everything was painstakingly dry fit into place. Shingles and edge would be blown to kingdom come in a storm. It looked like it was going to be a doozy. After a moment of cursing and staring stupidly to the south, I dropped what I was doing and fired up the compressor. I had originally intended to simply tack the edge into place with staples before nailing it with roofing nails and adhesive. I didn't even buy the nails yet. I grabbed the 18GA Stapler , scurried up the ladder, and started rapidly banging away. An adjustment to the depth wheel and it was sinking staples through shingles and edge easily, with the occasional spark from hitting granules.

It looked like the storm might just pass to the west. I got the garage face nearly fastened when a big boom from behind startled the absolute crap out of me. It was coming my way after all.

The stapler kept its cool and said, "Bang-ity, bang! bang! bang! bang!" getting me nearly to the end for the garage facia before the initial drops, preceding a cold sheet of rain hit me in the back.

* Heck, it almost never rains anyway.

Idiot.

So much for that. How are your morning plans working out?

______________________________________________

PS - A PORTER-CABLE 3-Tool Combo Kit is one of the very best tool investments I've made for renovation projects and woodworking. It's small and portable. I use mine with its included guns, as well as a big 2-Inch to 3-1/2-Inch Framing Nailer, filling tires and pool toys, and blowing stuff off with a blast of compressed air. - John

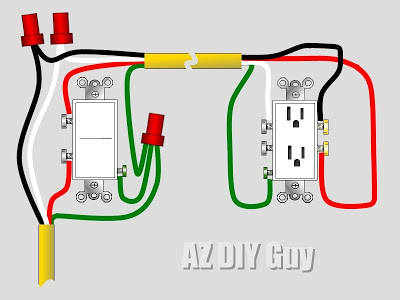

Wiring a split, switched receptacle.

|

| I wonder if there's a prize in this box? I think that's what Prises Contactos means. |

To split a receptacle, there's an easy trick. There's a little bridge between the terminal screws on the "hot" ("un-grounded conductor") side of the device. The "hot" side has brass color screw terminals and is on the side that has the smaller, vertical slot on the face.

.

|

| Pro tip: Don't stick a sharp pencil, such as this one, in your eye |

This bridge is a jumper that lets the current flow from one feeding wire attached to either of the screws or rear, push-in connectors to both of the outlets on the face. Break the bridge and the current won't flow between the top and bottom outlets. It can be done with needle nose pliers and some serious wiggling, or with some diagonal cutting pliers.

|

| Snipped! |

I leave the bridge intact on the neutral side ("grounded conductor" or "common") with the silver screw terminals.

Ready to start? You know the drill...

|

| Circuit breaker = OFF!!!! |

|

| horrid, low-light cell phone shot. |

I didn't have time to build it to scale or paint it.

|

| Split receptacle with 3 wire + ground cable |

I was very lucky in that there was an extra wire from the switch to the outlet that I wanted to control. There was a second dummy switch at the door. I guess the 1979 electricians had pre-wired for it, but the original buyer didn't want to pay the up charge. But, there's another way, if there's no third wire. It requires that the feeding (line) side hits the receptacle first. It's a little harder to follow.

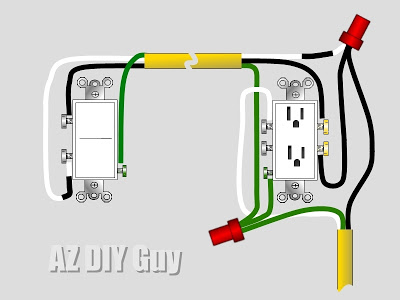

|

| Split receptacle with 2 wire + ground cable |

Confusing eh? This is a perfect example of why I don't ever trust color. There's current on one of those white wires. Cross them up and you've created a direct short. Turn on the circuit breaker, flip the switch, and the breaker will trip (hopefully).

The black feeds half the receptacle and ties directly to the white conductor headed to the switch. The switch-leg comes back on the black wire when the switch is active. Switches don't use a neutral. The re-tasked white wire should be marked with black tape to signal it's change to a "Hot" conductor. The receptacle still does get a neutral in order to work properly and a ground for safety.

It's a common practice to install the switched plug "upside-down" compared to the rest of the room, ground prong side up. It's easily recognizable.

Look like a pro tip: vertically line up your plate mounting screws. Don't leave it looking like a cross-eyed orangutan installed it.

|

| Upside-down you're turning me...

- Diana Ross (apparent electrician)

|

AZ DIY Guy's Standard Scary Warning - Electrical Edition: Don't mess with electrical, unless you know what you are doing. 120 volts of household current can kill you just as dead as much higher voltages, it just lets you suffer longer, and folks can recognize you in your casket. Plus, electrical issues can do a heck of a job burning your house right to the ground. When in doubt, get a professional electrician. If you do the prep work, this project is a snap for someone who's trained; it shouldn't cost too much. Even if you know what you are doing, I recommend you work it like it's live, even if it's not. Research legal requirements in your area before making changes to your electrical system. Don't take my word for this stuff, I might be an idiot.

Mounting a new address plaque

|

| Ok, ... DIY Guy, ... what the heck does that say?* |

|

| It's so sad and lonely down there. |

|

| Well, isn't this is an unflattering, weak-chinned angle. |

|

| Official Klein Klein anchor tapping tool |

|

| Official Klein Insulated plaque screwdriver |

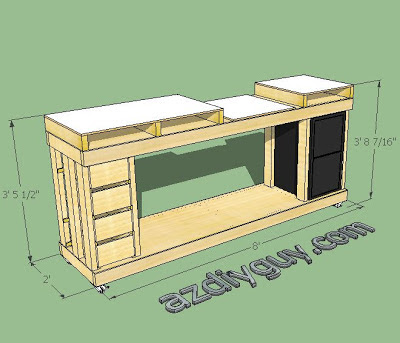

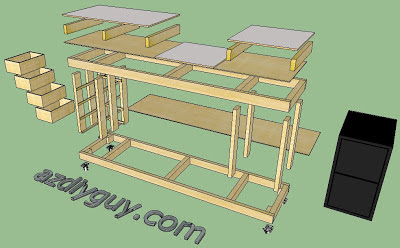

SketchUp: Modeling my miter saw workbench

|

| It's easier than it looks! |

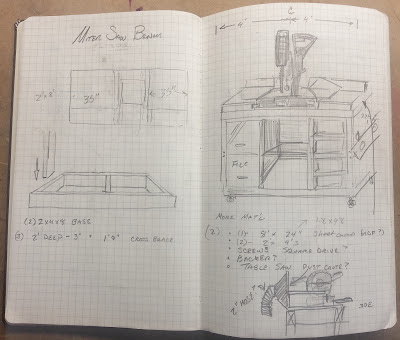

Apparently, I like to do things completely bass-ackwards. I built this project first in the real world, many-many months before introducing it to the digital realms. I had done a quick and simple pencil and paper sketch in my Moleskine Classic Notebook ,

This bad-ass bench has been in real-word, front-line combat, supporting the mighty DeWalt 12-Inch Slide Compound Miter Saw

|

| Right before the maiden voyage. |

|

| This is exactly how Iron Man was designed. Exactly. |

|

| Because parts is parts |

- Vertical Structure: 10 ea. 2x4's (1.5" x 3.75" actual) x 29 1/4" long

- Bins: 4 ea. I actually built these for another project from 1/2" plywood and a 1/4" bottom. I used a dovetail jig, but it's not necessary for simple tool bins. 10.5" wide x 6.5" high x 16.25" long.

- Swivel Castors: 4 ea. I bought these 3" heavy-duty, locking swivel castors at Harbor Freight

- Bin Rack - back stop: 4 ea. - pine 0.5" x 1" x 14.25" (made from planed pallet wood)

- Bin Rack - rails: 8 ea. pine 0.5" x 1" x 21" (made from planed pallet wood)

- Top and Bottom Depth Structure: 10 ea. 2x4's (1.5" x 3.75" actual) x 21" long

- Base blocks: 4 ea. 2x4's (1.5" x 3.75" actual) x 3.75" long - for mounting the castors

- Top and Bottom cover: 2 ea. 1/2" plywood 24" x 96" (8 feet)

- Top and Bottom Width Structure: 4 ea. 2x4's (1.5" x 3.75" actual) x 96" (8 feet) long

- Work surface Center: 3/4" White thermally-fused melamine coated particle board 24" x 24"

- Work Surface Right: 3/4" White thermally-fused melamine coated particle board 24" x 23"

- Work Surface Center: 3/4" White thermally-fused melamine coated particle board 24" x 42"

- Two Drawer File Cabinet: (not shown above)

|

| No, it's not a Leonardo da Vinci original, but I see how you might think so. |

* All rights reserved - AZ DIY Guy's Projects: . I hereby give license to individuals to build this bench for their own use. My design, plans, images, and model and may not be used for profit without my express permission. This means you Ted's Woodworking Plans.