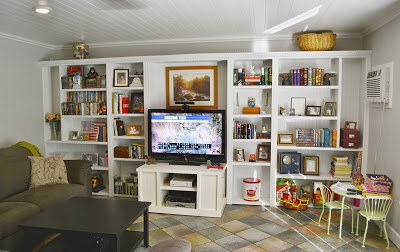

Jack's room is a den of tween, man-cave awesomeness. It's his fortress against the world, or at least against the constant onslaught of a pestering little sister. He spends a lot of time in there. To maximize space we'd gotten him a

loft bed from IKEA, with a built in desk.

Problem: the blades of his ceiling fan spun right through the sleeping area. I told him to scoot over against the wall and not roll around much, but Sweetie convinced me Child Protective Services would have an issue with my solution. So, I removed the fan and installed a simple light fixture. Unfortunately, during the hottest summer nights, it's been warm for him, up by the ceiling. A floor fan just doesn't cut it.

We saw an

oscillating ceiling fan on display at Home Depot and decided it would be perfect for him. We'd direct it at his bed and get him some much needed air flow. What a cool idea! I've installed plenty of ceiling fans over the years, this was an odd one, but it shouldn't take more than a few minutes,...

right? (Remember

Murphy's Law?)

With the power off, I took down the old fixture. I capped off the wires and installed the mounting bracket that came with the fan. I'd forgotten about the ceiling damage from the old fan that was hidden behind the larger fixture.

Again, please excuse the shabby cell phone pictures folks. I'm still working on a replacement for the camera.

Jack got some tool time in with the assembly of the fan.

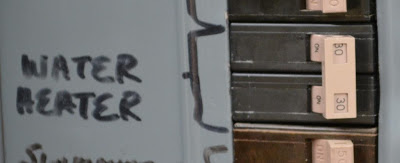

I popped the fan onto the bracket and prepared to make the electrical connections.

|

| See the black AND blue wires? |

I say "prepared", because that's as far as I got. Why? because I was an over confident

putz. In my steely-eyed, experienced-fan-installer confidence, I hadn't even glanced at the instructions. I hadn't paid any attention whatsoever to the fact that this fan had two wires, one to control the fan, the other to control the oscillating.

The existing house wiring only had one wire. Moooooron.

I've used awesome add-on

electronic solutions

in the past to solve this single-switched wire problem when using a fan / light combo, but this unit comes with its own control switch. It requires two wires. I need to install another wire from the switch box to the fan. You know what that means,... in Phoenix,... in the summertime,... in the afternoon...

|

| Attic work. I hate attic work. |

It was easy to find the ceiling box quickly (It's hot up here.), and trace the cable to where it dropped down the wall, towards the switch (It's hot up here). I needed to replace that section of 2 conductor cable with 3 conductor cable (It's hot up here). I gave it a gentle tug (It's hot up here) and figured that it felt loose enough to pull out, no staples (It's hot up here). I scurried back down into the sweet cooling embrace of air-conditioned space.

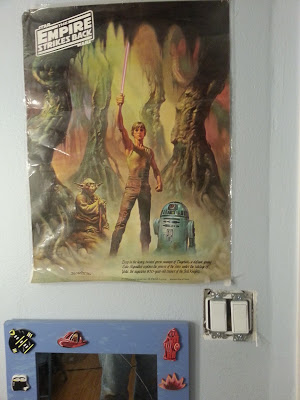

I popped into the switch box, below the Empire poster. Anyone know where I got this poster,... a loooooong time ago?

Fishing attempt #1: (By using the word "attempt", and numbering it, savvy readers will recognize that I'm about to introduce a failure). I tied attached the new cable to the old one and wrapped it with electrical tape in a long tapered head. I had Jack gently feed it into the wall, while I pulled from above (It's hot up here).

Nothing. We made it an inch. I stopped pulling when I felt initial, heavy resistance (It's hot up here). There's no point in skinning the wire up due to a staple. Fail.

Fishing attempt #2: I broke out the ol' fish sticks. No, not

this variety, but a set of

Klein Glow Rods

. These are great for getting through hard to reach areas. I've had tremendous luck in the past.

I poked around for a bit but could not access the proper spot from above (It's hot up here) or below. There was a duct immediately above the switch, blocking the wall cavity. The existing cable entered through a hole at an odd angle. FAIL

Fishing attempt #3: A

fish tape?

. Nahhhh... The last thing I want to mess with in the attic

(It's hot up here) is a coiled mess of fish tape in all that god-awful insulation. Didn't even try. FAIL

Fishing attempt #4: In walls without insulation, I've had good luck with weight on a string. I Mac Gyver'd this feat of modern engineering with a string line and some 1/4" nuts.

|

| W.W.M.G.D. = What would Mac Gyver do? |

Then it was a matter of drilling through the top plate. I used a

large extension

and a 3/4"

spade bit

, at an angle to penetrate below the duct work

(It's hot up here).

|

| Here's my rig. |

|

| Hmmm... AZ DIY Guy, It doesn't look to miserable in the picture. |

This is one of those times where a

good cordless drill

is a must. Stringing an extension cord through the itchy attic mess

(It's hot up here) would be another exercise in misery. I like a bigger 1/2" chuck drill too.

I dropped the weighted string down the hole (It's hot up here) and landed it directly on the top of the switch box, first try!!!. Success!!! I clambered back down (into air conditioned sweetness) and fished the string out with the hook on the fish stick.

Back up top (It's hot up here), with Jack feeding from below, I slowly pulled the string with the new cable attached. I managed to get it plenty clear of the hole, when it got hung up on something. There was no way I was going to tug on it and strip the wire in the wall. I cut my losses and stopped. I'll splice it in the attic (It's hot up here).

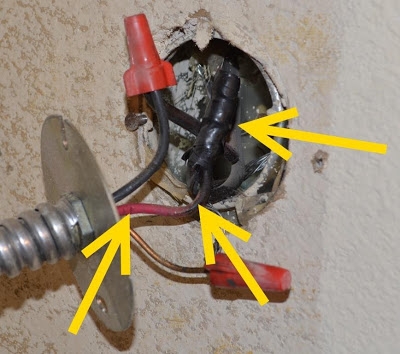

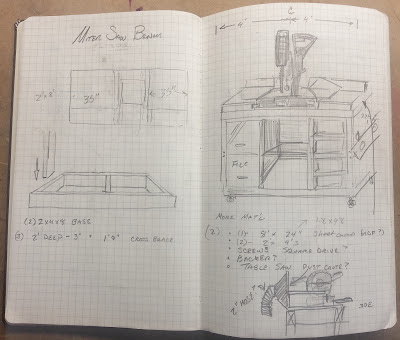

I did not want to spend one more second than necessary in a 140 degree attic (It's hot up here), so I prefabricated my splice box down in the workshop.

Back in the foul darkness (It's hot up here). I screwed the box down, clamped the cable, made the splices, installed a few staples and stuffed the cable into the fan box.

It's hot up here: In case I hadn't mentioned it. It was a bit toasty, especially in my long sleeve shirt and jeans. I forgot my dust mask on that last ascent into hell.

|

| Crazy from the heat. |

Seriously folks, attics are no place for dilly-dallying in the summer, not to mention in Phoenix on a 106 degree day. I took good breaks in the cool, stayed hydrated, and kept my visits to less than 10 minutes. It still sucked, but I got it done and managed to avoid a heat stroke and fall through the ceiling. I don't recommend it.

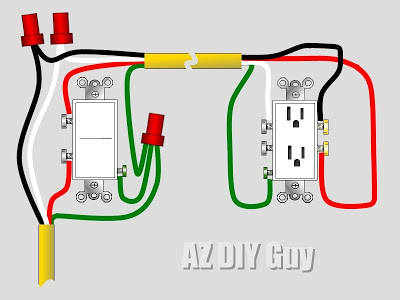

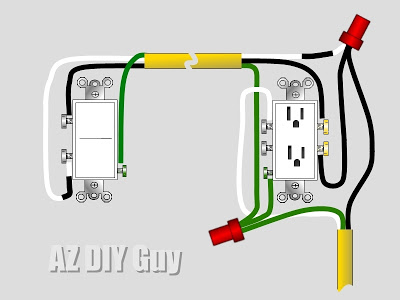

Back on earth, I had a nice fresh piece of 12/3 w/ ground NMC ("Romex") to work with.

The included switch went in easy. It has a speed selector and an oscillate switch. The other toggle switch now controls a switched receptacle to control a floor lamp, for lighting. We now had no ceiling light fixture. My exciting post on installing a switched split receptacle can be enjoyed

here.

Installing the fan the rest of the way was pretty standard stuff. No problem at all.

It looks great and works well. It cools nicely at the desk below. BUT, dang-it, it won't oscillate high enough to blow into the bed. It's a total miss. I couldn't rotate it until I powered it up to learn that it wouldn't go 90 degrees to the ceiling; it goes about 45 degrees.

The other issue is that there's some wobble in the entire fixture as it oscillates. I'm going to have to brace it up tighter. I'm not comfortable with all the movement on just two 8/32 screws holding it up. I also don't like the direction to periodically tighten the screws. It seems they'd solve that in the design.

I may see if I can safely disassemble it and slip a couple gear teeth to get the thing to shoot sideways. Either way, Jack's enjoying it while he

Minecrafts his summer vacation away.

Enjoy the cool breeze my friends.